Retort pouches as a daily pouch were widely used in our kitchen life. It’s a good assistant for us. For those a thousand types of retort pouches, do you really know what exactly are retort pouches? Or how’s work for our life? What’s special of the material and how’s the standard of those food packaging?

In this article, we’ll show you the answer! Let’s get to know more!

Made from heat-resistant laminated plastic, retort pouches are semi-rigid, flexible packages. Food products like soups, pasta, rice, sauces, and cook-in-a-bag meals are sealed and sterilized in these pouches with a maximum temperature of 121°C. Thus, they are the go-to packaging for convenience, processed, and pre-packaged food.

The history of retort pouches

The idea for retort pouches was promoted by the US army in 1950 and the research continued through 1960. It was finally invented by United States Army Natick R&D Command, Reynolds Metals Company, and Continental Flexible Packaging and was first introduced in Italy. These companies received the Food Technology Industrial Achievement Award for their invention in 1978.

Change is sweeping through supermarkets. Products once used for canning can now find a home in a new packaging medium, the stable vertical packaging bag.

We have never seen so much packaging innovation in such a short period of time. Pet food manufacturers, seafood manufacturers, and other food manufacturers have begun to consider this new way of customizing food packaging to make their products more attractive to consumers. Cookable pouches offer many advantages over traditional tin cans.

These pouches faced a stagnation period in the beginning due to the reluctance of the people to accept them. However, over the years manufacturers and companies have realized that using retort pouches for packaging reaps many benefits.

Inside of retort pouches

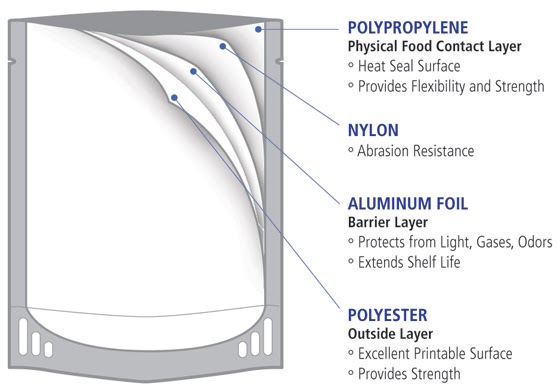

When we wax praises about how well retort pouches package, it is because of its internal structural composition. It has the sturdiness of metal cans and protects the nutrient value of the food. Specifically, each pouch consists of four layers as shown in the image below.

- The first layer is propylene which acts as a heat seal surface and provides strength and flexibility.

- The next layer which is the nylon layer protects from abrasion.

- The aluminum layer not only protects from lights, gases, and odor but also extends the product shelf life.

- The final polyester layer provides excellent strength and is very easy to print on.

The materials that go into the packaging of retort pouches are FDA approved and undergo sterilization processes which increase the durability of the packaging.

The standard of retort pouch material

Durable retort pouches for ready-to-eat food

Although all stand-up and barrier bags are made of special laminates to protect food from spills, punctures, and external contaminants, foods designed for fast and easy cooking require special films.

The retort packaging is a unique form of self-supporting pouch used for bagged food and side dishes such as soup, rice, sauce, and pasta.

The food-grade, FDA-approved materials used to construct this type of packaging undergo a sterilization process to extend the shelf life of internal products while increasing the durability of the packaging itself.

After going through the retort, the food and packaging can withstand temperatures up to 250 degrees, making it a perfect solution for microwave meals.

Due to its strength, flexibility, and lightweight, retort pouches have become a widely used alternative to traditional canning methods to preserve food and keep it fresh for many years.

These sachets use less than 5% of the traditional hard can packaging materials and help improve food quality, texture, flavor, and aroma.

Foods can be pre-cooked or eaten raw before being put into retort packaging. Compared with traditional rigid containers, their sterilization speed is faster and the temperature is lower. By using scientifically developed layers and bottom gussets, these pouches can be placed vertically on shelves and in microwave ovens, allowing consumers to easily find them in store aisles and leave them at home. The upright structure also helps maintain the shape and composition of the internal product during rapid cooking.

The retort pouch can be customized using the rotary gravure printing process to create a rich and vibrant design on the outer layer of the package. Like all the products offered, the retort packaging meets our high quality standards:

FDA approved food-grade material

Water-based ink

ISO and QS quality rating

Excellent print quality, no matter the size of the order

Recyclable and landfill friendly

Material of retort pouches

The structure of the high-temperature resistant cooking bag has two layers, three layers, four layers, and even more.

Among them, the second layer is a transparent plastic/mold, such as PET / CPP or OPA / CPP.

The three layers are transparent plastic/mold, such as PET / OPA / CPP, and opaque types containing aluminum foil, such as PET / AL / CPP, OPP / AL / CPP.

The four layers are opaque PET / AL / OPA / CPP with aluminum foil. This structure is a puncture-resistant, reinforced, large-capacity packaging bag. The OPA should be reasonable between AL and CPP.

The more layers are mainly The inner layer does not use pure CPP film, but uses multi-layer co-extruded film, such as PA / EVOH / PP, PA / PVA / PP co-extruded film plus PET or aluminum foil to form a composite with more layers, but its quantity Not much.

From a functional point of view, the four-layer structure PET / AL / OPA / CPP bag containing aluminum foil can completely meet the requirements of all cooked food.

For these materials used in cooking bags, it is necessary to introduce their properties and functions. In order to ensure the quality of cooking bags, specific requirements should also be put forward.

1. Polyester film PET, also known as biaxial (or biaxial) stretch polyester film

PET (or BOPET) film is used as the outer material of the cooking bag, and its thickness is 12 μm. It has the characteristics of high melting point, high heat resistance, high mechanical strength, high rigidity, high transparency, high odor resistance, and high gas resistance. Due to the polarity relationship in its molecular structure, the surface tension is high, and it is slightly increased. The surface tension after corona treatment can reach 52mN / m (ie 52dyn / cm), which is very favorable for printing and binding.

When PET is used as the outer layer material and other heat-sealable materials (CPP, PE, etc.) are compounded to heat-seal bags, even if the temperature is as high as 220 ° C, it will not melt and deform, and will not stick to the knife. Bag making. At present, there are many PET film production suppliers in China. Most PET films can meet the high-temperature cooking of 120 ~ 128 ℃, and even meet the high-temperature cooking of 135 ℃. However, there are also some PET films with thermal shrinkage. Large, the problem of deformation after high-temperature cooking. Therefore, when choosing PET for high-temperature cooking, be sure to choose a product with a small heat shrinkage ratio, and then use it with confidence.

2. Aluminum foil AL

Aluminum foil is a metal material. Most of the soft aluminum foils with a thickness of 9 μm are used on the cooking bags. Airtight (O2, N2, CO2, etc.), opaque, and extremely high heat resistance and oil resistance, so the composite bag made of aluminum foil has a full seal (like tinplate cans), high security It has excellent properties such as oil resistance and high-temperature resistance. It is the highest-grade composite flexible packaging material.

3.Cast polypropylene CPP

In cooking bags, as the inner material that contacts food contents and heat-sealable bags, most of them are unstretched cast polypropylene films with a thickness of 70 μm to 80 μm. Only a few use high-density polyethylenes ( HDPE) Manufactured at 121 ° C.

High-temperature retort pouches – as one of the most commonly used cooking bags, its trial materials and standards may be higher. Do you know the high-temperature retort pouches?

What’s High- temperature retort pouches?

“The high-temperature cooking bag is a kind of composite plastic film bag that can be heated. It has the advantages of both a canned container and a boiling water-resistant plastic bag. Sterilized and heated, ready to eat. After more than ten years of use, it is an ideal sales packaging container.

Types of High-temperature retort pouches

Classification by structure:

Class A: PA / CPP, PET / CPP. Amount of water vapor transmission: ≤15g / (m㈠4h); Amount of oxygen transmission: ≤120cm / (m2㈠4h0.1HPa).

Type B: PA / AL / CPP, PET / AL / CPP. Water vapor transmission rate: ≤0.5g / (m (4h); oxygen transmission volume: ≤0.5cm / (m㈠4h0.1MPa).

Type C: PET / PA / AL / CPP, PET / AL / PA / CPP. Amount of water vapor transmission: ≤0.5g / (m㈠4h); Amount of oxygen transmission: ≤0.5cm / (m㈠4h0.1MPa).

Classified by cooking temperature

When the relative pressure is 110 psi, the corresponding temperature is l15cC; the shelf life is about 3 months.

When the relative pressure is Ps 1 15 psi, the corresponding temperature is 121cC; the shelf life is about 6 months.

When the relative pressure is PS 1 20 psi, the corresponding temperature is 126cC; the shelf life is about 12 months (transparent bag).

When the relative pressure is PS1 30 psi, the corresponding temperature is 135cC; the shelf life is about 24 months (aluminum foil bag).

Of course, the shelf life has a lot to do with the barrier properties of the cooking bag and the type of food.

How to test the retort pouch?

(1)sealing test

Through blowing up the compressed air in the retort pouch and underwater extrusion, we can test the sealing performance of the material.

We can effectively evaluate the sealing performance to get basis information for determining the process indicators.

(2)pressure resistance and drop resistance test

Through the test of drop and pressure resistance, you can have a clear understanding to the resistance to rupture performance and ratio during the turnover process.

Anything can happen during the transportation, you have to do the pressure test for a single package and a drop test for whole box of products.

Besides, you need to do multiple tests in different directions, in order to get a comprehensive date.

That’s how you can solve the problem of product damage due to the transportation

(3)Mechanical strength test of retort pouch

The mechanical strength of the packaging materials include the composite peel strength, sealing strength, tensile strength, etc.,

if the test index can not meet the standard, it’s easy to break or fracture in the process of transportation.

Such parameters can be tested by universal tensile tester which meet the national and industry standards.

(4) Barrier performance test

Retort pouch are generally packed with highly nutritious contents such as meat products, etc.,

These products are susceptible to oxidation and deterioration. Even in the shelf life, its taste varies with the date, so to ensure its nutrition, flavor and quality, the packaging should use the material which are able to prevent the product from outside space.

That’s why it’s necessary for strict oxygen and moisture permeability test

(5) Residual solvent testing

Printing and compounding are two very significant steps during the production of retort pouch the use of solvents in the printing and compounding process is necessary.

The solvent is a polymer chemical materials with certain irritating odor, which is harmful to human body.

Every countries has relative lows to control the uses of these solvents

so during the printing process of semi-finished products, composite semi-finished products and finished products production , we have to do the solvent residue tests to ensure that the products are healthy and safe.

Therefore, printing semi-finished products, laminated semi-finished products and finished products are need to be tested for solvent residues to ensure that the products are healthy and safe.

Benefits of retort pouches packaging

The retort pouch has been developed as a flexible laminated food package that needs to withstand the heat treatment.

There are many benefits to using retort to package food. Foods can be raw or pre-cooked before being put into retort packaging. Compared with traditional rigid containers, they have a faster sterilization speed and a lower temperature.

One of the main benefits of manufacturing is that processing time is usually greatly reduced compared to processing in cylindrical containers.

Other advantages are that packaging requires smaller empty container storage space, easy to package and display, and can also reduce your transportation costs.

Sachets have become very popular and have been widely accepted by consumers.

Because they are strong, light, and versatile, retort packaging has become a widely used alternative to traditional canning methods, which can be used to preserve food and keep it fresh for a longer period of time. They use less than 5% of the packaging materials of traditional hard metal cans, and they help improve the flavor, texture, and aroma of food.

The stand-up pouch is made of a special laminated layer to protect food from spills, punctures, and external contaminants, and a special film is designed for foods that require fast cooking.

The retort packaging is ideal for items such as soups, rice, sauces, and pasta. If you are looking for the best quality retort packaging that Australia must provide, please contact us immediately.

However, those kinds of retort pouches are commonly used in our life right now while they do help to save the day! Let’s see:

Well-designed

Due to the sturdy packaging, these pouches are protected during transportation. Being lightweight, they also prove to be very cost-effective during transit. They can easily withstand temperature variations of up to 250 degrees and are leakage-proof.

Resource-efficient

Retort pouches utilize just 5% of the packaging material and at the same time improve the food texture, flavor, and aroma. Also, the energy that goes into the production of these pouches is much less than what goes into making metal, paper, or glass packages. They are made with high-quality materials and are environment-friendly.

Space-efficient

Retort pouches can stand upright on the shelves and this helps in maintaining the food composition inside. They are also flat and hence take up very little space on the shelf as well as in the shopping bags.

Combinedly, all of the above advantages serve to make retort pouches the go-to packaging, especially in the food and beverage industry.

8 Advantages Of Retort Pouch Packaging

The retort pouch packaging is a composite plastic film pouch that can be heat treated. It has the characteristics of both a canned container and a boiling water-resistant plastic bag. Therefore, it is also called a “soft can”.

The retort pouch is made up of three layers of materials. The typical retort pouch structure is: the outer layer is a polyester film for reinforcement; the middle layer is the aluminum foil for light, moisture, and leakproof; the inner layer is polyolefin Membrane (such as polypropylene film) for heat sealing and contact with food.

In terms of food packaging, retort pouches have many unique advantages over metal cans and frozen food pouches.

Here are the 7 major advantages of retort pouch packaging:

1. Maintain the color, aroma, taste, and shape of the food. The retort pouch is thinner and can be sterilized in a short period of time, and the original color, aroma, taste, and shape of the food are preserved as much as possible.

2. Easy to use. The retort pouch can be opened easily and safely. When eating, put the food into the boiling water together with the bag and heat it for 5 minutes to open it, even if it is not heated.

3. Convenient storage and transportation. The retort pouch is light in weight and can be stacked and stored.

4. The space occupied is small. After packaging the food, the space occupied is smaller than that of the metal can, and the storage and transportation space can be fully utilized to save the storage cost.

5. Save energy. Due to the thinner retort pouch, the bacteria can reach the lethal temperature faster when heated, and the energy consumption is 30-40% less than that of the iron can.

6. Easy to sell. The retort pouch can be packaged or assembled according to market needs, and customers can purchase it at will. In addition, due to the beautiful decoration, it also greatly increases the sales volume.

7. Long save time. The food packaged in the retort bag does not need to be refrigerated or frozen and has a stable shelf life, comparable to metal cans, easy to sell, and is convenient for home use.

8. Low manufacturing costs. The composite film for manufacturing the retort pouch is lower in price than the metal sheet, and the production process and the required equipment are much simpler, so the retort pouch is lower in price.

Lanker retort pouches are available in a variety of accessories, including easy-to-tear, nozzle, zipper, transparent window, etc., to withstand temperatures from 120 ° C to 135 ° C.

Lanker retort pouch is strictly in accordance with international standards for quality control and is certified by the SGS testing organization for BRC and ISO certification, in line with international food safety standards.

Popular uses for retort pouches packaging

You can put almost any processed food or beverage you can think of into the cooking bag. Pet food manufacturers often use them to package wet foods and snacks.

The choice that consumers can pierce with a straw is suitable for juice and yogurt drinks. They are a good choice for ready-to-eat main dishes such as curries, pasta with sauces, and other pre-cooked dinners.

Manufacturers also use these containers for soup, rice, and pre-cooked vegetables.

Pet products, including snacks and wet food

Juice and yogurt drinks

Ready to serve dinner main course selection

Soup, rice, and delicious pre-cooked vegetables

Disadvantages of distillation packaging

Retort pouch packaging has two main disadvantages: initial mechanical cost and process complexity.

It requires highly specialized filling, heat treatment, and tensile strength testing equipment. The purchase and maintenance costs of these machines are often high.

Production complexity is another potential stumbling block. In order to properly heat-treat sealed bags, manufacturers must consider several factors, including residual air and packaging thickness.

Two other potential difficulties include slower filling speeds and the need to provide additional protection during transportation. Filling technology is often slower than canning technology.

Depending on the type of container you choose, you may need to provide additional packaging during the distribution process to minimize the chance of accidental punctures.

The market analysis of retort pouch

In terms of value and quantity, it is expected that from 2020 to 2025, the small bag segment will lead the distilled packaging market.

According to the type, the sachet segment is expected to become the largest market for retort packaging. The dominant market position of the bag can be attributed to its durability.

The growth of this segment is attributable to the increasing demand for its product packaging from the food and beverage industry.

The characteristics of retort bags, such as lightweight, smaller spacing, and longer shelf life, make them a suitable substitute for tin cans.

In terms of value and volume, the food end-use portion of the retort packaging market is expected to be the largest market.

Food includes ready-to-eat food, meat, poultry and seafood, pet food, baby food, soups, and sauces.

It is an important contributor to the growth of sterilization packaging. Retort packaging has revolutionized the food industry.

It promotes the development of food supply channels and helps supply seasonal food throughout the year.

Due to demographic changes, consumers are looking for more convenient ways to eat their food without too much trouble.

Drivers, constraints, and opportunities

-Driver

Changes in lifestyle due to busy schedules have led to increased dependence on processed foods. This is expected to further promote the growth of the distillation packaging market.

In addition, the rapid growth of the food and beverage industry and the increasing consumer preference for mobile food and beverages are other factors that are expected to promote the development of the retort pouch packaging market.

In addition, rapid globalization has led to an increase in the global processed food trade, which will promote the growth of the retort packaging market.

– Constraints

However, people’s increasing attention to healthy and hygienic foods is considered to be a restrictive factor in the retort packaging market.

-Opportunities

On the other hand, the government’s incentives and funding for the food processing industry in China and other emerging countries can create huge opportunities for the cooking and packaging market.

COVID-19 scenario analysis of retort pouches

Due to the cessation of manufacturing and a significant reduction in global demand for luxury goods and non-essential services, the COVID-19 crisis may have a negative impact on the retort packaging industry.

The impact of the COVID-19 crisis on the packaging industry is mixed, mainly due to the closure of physical retail stores around the world. However, the availability of online retail has absorbed the severe effects of this shutdown.

Demand for e-commerce specific packaging is likely to remain strong, although e-commerce companies will have to focus on product protection and packaging disinfection.

In addition, the food packaging industry is at the forefront of the global packaging market, mainly due to the demand for basic products such as groceries and fresh food from local e-retail sites.

Due to the decline in demand for non-essential goods in the first two quarters of 2020, industrial, transportation and bulk packaging are facing a sharp decline.

Due to the decline in the disposable income of the largest population and the weak demand for packaging for industrial products, the packaging industry may face tremendous pressure to reduce wholesale and retail costs.

Consumers may be hesitant to spend on luxury goods, travel and hotel services, which is expected to hinder the future growth of the packaging industry after the COVID-19 crisis.

The impact of retort pouches on life and career

Retort pouches have penetrated people’s lives and businesses.

The position in personal daily life and packaging business is becoming more and more important.

Next, I will talk about the impact of Retort pouches packaging from both personal life and business aspects.

(1) Retort pouches play an important role in personal life

Suppose there is such a scenario:

On a wonderful weekend, you and your family will have a picnic outdoors.

Delicious food cannot be absent.

But the problem is how to package delicious food. And how to take it out intact?

At this time, it is time for the Retort pouches to work.

You can bring a variety of delicacies prepared in advance.

Put these foods in retort pouches and don’t worry about the soup overflowing and the food will go bad.

When you share delicious food with your family, you will spend an unforgettable weekend.

On the other hand, if there is no food in the cooking bag, a lot of large and small lunch boxes are needed to store the food, which will take up a lot of space.

The soup may also overflow. If the food goes bad, what a bad weekend it will be.

Another example:

In another situation, you are an office worker and have a short lunchtime.

But I don’t want to eat takeaway, and I don’t have time to go home and cook.

At this time, the Retort pouches are on the stage.

You just need to take out the food prepared in the morning.

The next step is to heat it in a microwave.

Just wait a few minutes and you can enjoy a healthy, time-saving, and delicious lunch.

If you want to carry delicious food with you, steamed food is the best choice for today’s fast-paced life

(2) Retort pouches occupy an important position in the packaging business

“Business opportunities are like buses, there will always be another one.”-Richard Branson.

The question is: are you ready when the opportunity comes?

If you want to start your distillation packaging business, but are not ready yet.

I will help you learn more about retort pouches and how to do business.

The first thing you need to know is the changes in the packaging market.

The packaging industry is moving in a more convenient and environmentally friendly direction.

Steamed food is becoming more and more popular.

The search volume of retort pouches in the whole network exceeds 6000, and it is still growing.

This means that more and more people are starting to operate the retort pouches business.

So what does this mean?

This is a huge market.

You should have more Retort pouches on your shelf.

take this opportunity.

Otherwise, when others dominate the market, it will be too late for you to work hard.

Knowing yourself and the enemy is the only way to survive in every battle.

The purpose of marketing is to understand customers in depth.

Let our products meet the requirements of customers, and finally, let the products be self-sold.

The most important thing in doing business is to be good at analyzing market dynamics.

When the opportunity comes, seize it.

Where there is demand, there is a market. Where there is a market, there are opportunities to make money.

If you want to start a distillation packaging business, you should take everything about distillation bags.

What kind of food is suitable for cooking bags

(1) Field rations

Not everyone works in the city.

There are some special workers whose work is far away from the city.

In the wild or even on the high mountains. There are no salty vegetables or food there.

They did not work there for a day or two, but several years. So, how to let them eat delicious food?

This is a very critical issue. Distillation packaging is a boon for these workers.

They can eat what they want in the city, so they are in great demand.

(2) Air food

Like the needs of field workers, aerospace workers also have problems in this regard.

The dietary needs of space workers are more difficult because they work in space.

Their food packaging requirements are higher.

The problem of being overweight must be overcome in space.

The good news is that we solved this problem.

The bag can be left on the space station to provide food for the astronauts and ensure their nutritional needs.

(3) Seafood

Many people live far away from the sea.

They cannot eat fresh seafood all year round.

Because it seems that the shelf life is only 1-2 days, or even shorter.

We know that the sooner you eat seafood caught from the sea, the better. Therefore, people living in inland areas cannot eat fresh seafood.

To solve this problem. This is a special consideration when developing retort packaging.

After the seafood is salvaged, clean it immediately and put it in a cooking bag.

And immediately carry out high-temperature sterilization treatment.

The original flavor of seared seafood. When opened again, the taste is the freshest.

(4) Camping food

More and more people want to live outside the city.

More and more people want to travel on the go.

Finding beautiful scenery in nature is a great way to relax.

But how can there be no food to accompany you on the road?

Choosing food packaged in sterilization bags is the choice of more and more wild travelers.

Bring food, bring a good mood, embrace nature, and enjoy a good time.

4.How do you use the sterilization bag

The use of distillation packaging is very simple.

If your home or company has a microwave oven, you just need to put the bag in the microwave oven.

You can enjoy the food in 2-3 minutes.

If you are outdoors, but the sterilization package in boiling water and blanch for a few minutes. For food that does not need to be heated, just open the bag to eat.

Top 5 high-quality retort pouch suppliers in Australia

1. Vivo

Vivo Packaging is committed to ensuring the provision of high-quality packaging products. This company has different departments responsible for different obligations. This allows them to narrow their focus and create quality products every time. They work with qualified employees who have many years of expertise in the manufacture of packaging products. This allows them to produce high-quality products every time.

Their product range is very wide and it is a good choice for customers who need to see different options. The disadvantage of this company is that they do not provide printing services. This means that once you get a packaged product, you need to work with a printing company to classify your brand.

The feature of Vivo packaging is a spout bag carefully designed and made with high-quality materials. This allows them to hold liquids for a long time. The company has 2 factories, 2 departments, 2 warehouses, and 2 offices. With this, they can easily perform daily tasks to ensure they provide the best. They are located in Victoria, Australia.

2. Fine pack

The fine pack focuses on creating packaging solutions for different industries. They specialize in food and beverages, gifts, clothing, and agricultural products. They have a wide range of packaging options, with quality and function in mind when manufacturing. This company pays attention to its customers and realizes that printing services are an indispensable supplement. They strive to ensure that their customers’ brand image shines by ensuring that all designs meet high standards.

The best part is that they have custom designs that allow customers to comment on how they want everything to happen.

This is a great way to ensure that all your efforts to create the perfect package are rewarded. The company uses gravure printing and digital printing technology to ensure that all customer designs meet expectations.

This company prides itself on ensuring that its customers receive the best service.

This is why they themselves regularly review their systems and processes. This allows them to see where they can improve and how they should use their expertise.

They also pay attention to custom comments to make sure they solve all the issues that caught their attention. They are located in Leighton Square in Hornsby, Australia.

3. Of pack

Of pack is a manufacturing company that specializes in creating high-quality packaging options for customers.

The company was founded in 2016 and has grown and grown over the years to innovate its systems and processes. This allows them to accept new technologies and flexible packaging manufacturing options.

They are proud to provide products suitable for the needs of different industries. Their products guarantee quality and high performance to ensure that they meet customer needs.

They work with a group of qualified employees who have more than 50 years of comprehensive expertise in the field. This shows that they are proficient in their production process and will provide quality products.

Given that customers also need to print on their packaging, the company offers ready-made packaging options. This means you can let them finish printing to reduce hassle and pack and sell your products faster. Their series of spout bags are designed to provide great convenience and are manufactured with the highest quality.

The company is located in Melbourne, south of Oakley, Australia, and has international offices in other parts of the world.

4. Logos pack

Logos pack was established in 2004 and has always been the world’s leading manufacturer of flexible packaging. They work hard to ensure that all their products are of high quality and meet customer expectations. This allows them to gain the trust of their customers and earn a reputation for themselves. They have a team of experienced employees to ensure that all their products are manufactured in accordance with the highest standards.

They are well versed in the latest technology to ensure that all their processes are as efficient and cost-effective as possible. With this, you will find that the price attached to the packaging option is very friendly. They are a motivated company that aims to ensure that they contribute to sustainability and an eco-friendly environment. This is why they ensure that all raw materials are FDA approved and of the best quality.

This allows them to create products that can be used by customers for a long time and can reuse some products for different purposes. They have a wide variety of flexible packaging to meet the different needs of customers. Their spout bags are well-designed, made of high-quality materials, strong and flexible. They are located in China, but have established a strong influence in Australia, and have established systems and logistics to meet customer needs.

5. Primepac

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

With our team in China and Australia working as one, we reduce inefficiency so that you deal with one streamlined team from manufacturing right to delivery.

Service support team located in Guangzhou, the manufacturing hub of China, providing rapid response, and local industry knowledge. Warehouse and 3PL network located in Sydney, to provide rapid distribution, and delivery to your customers.

Conclusion:

According to the introduction, the retort pouches are different according to the material and the number of layers. During use, you can also choose different specifications and types of cooking bags according to different cooking environments and foods.

It is undeniable that retort pouches are indeed closely related to our lives. In order to meet the current public’s pursuit of environmental protection concepts, many manufacturers have also started to develop green retort pouches.

PrimePac is a manufacturer specializing in packaging production. It pays attention to every detail from material selection to production. Technological innovation is productivity and it is your trusted cooking bag manufacturer.

About Primepac

Primepac is Australia’s number 1 choice for plain and custom printed high-quality packaging.

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.