Food packaging is an integral part of food commodities. One of the major projects in the food industry process. It protects food and prevents the damage of biological, chemical, and physical external factors during the circulation of food from the factory to the hands of consumers. It also has the function of maintaining the stable quality of the food itself, and it is convenient for food consumption. It is the first to express the appearance of food and attract consumers. It has value beyond material costs. Therefore, the food packaging process is also an integral part of the food manufacturing system engineering.

Food packaging plays an important role in the industry, also it’s an indispensable presence in our life. Nowadays, more and more consumers choose green products. Thus, is undoubtedly an industry innovation for food packaging. From production standards to use standards, manufacturers have begun to focus on the development direction of eco-friendly protection and recycling technological innovation.

Let’s see the development of food packaging and the subsequent market situation! In order to boost your business, here are some key points you have to know about the food packaging industry!

Food packaging situation right now:

For some types of food packaging, the food contact material determines the name. A plastic bottle is made of plastic and has this material type in direct contact with the foodstuff. For glass jars, the materials in contact with the foodstuff are glass and coated metal from the closure.

In the case of beverage cartons, the direct food contact layer is not a carton, but laminated plastic. For aluminum cans, a coating is in direct contact with the beverage. Some types of paper can also be coated (for example with a grease-proof coating).

What are the requirements of food packaging in Australia?

If you're a food business, it's important to know what types of packaging are safe to use with your food products.

Under Standard 3.2.2 – Food Safety Practices and General Requirements, food businesses must:

- Only use packaging material that is fit for its intended purpose.

- Only use a material that is not likely to cause food contamination.

- Ensure there is no likelihood that the food may become contaminated during the packaging process.

Access the Food Packaging Infobite as a PDF here:

Food packaging is widely used in our life. You may also know a lot about the materials and types of food packaging. Let’s see how to choose food packaging materials that can also reduce pollution and maintain your health.

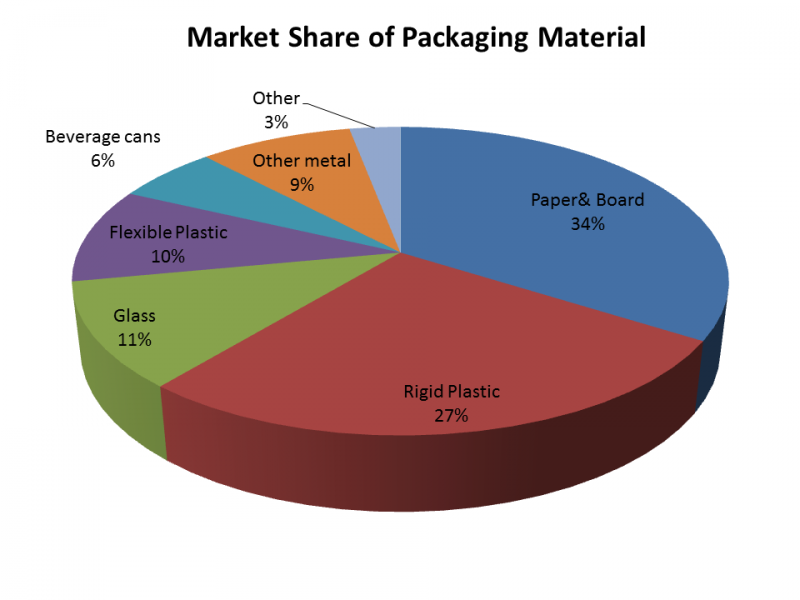

Types of packaging material used in food :

The most used materials in the food industry are detailed: plastics, glass, metals, and wood and its derivatives.

Wood, cardboard, and papers:

Products derived from wood are widely used in the packaging of food in the form of paper and cardboard. Paper is a very cheap, lightweight product with excellent printing capacity. Although it is very sensitive to moisture, it can be corrected with a combination of paper and other materials such as plastic or paraffin.

Cardboard is a material made up of several superimposed layers of paper, making it thicker, harder, and more resistant than paper. Its main use is for packaging and containers in the form of boxes.

In recent years, paper and packaging manufacturers are paying special attention to issues related to health and the environment by working with recycled products that increase the useful life of these raw materials. Therefore, some manufacturers try to used kraft paper packaging as one of the food packaging.

Plastics

Plastics are organic polymeric materials that can be molded into the desired shape. The lightness and versatility of these have been confirmed over decades in the processing and packaging of food. Plastic containers and packaging protect against the contamination of food and offer adequate mechanical strength.

Due to a lower cost and lower energy consumption during manufacturing, plastics have replaced traditional packaging materials. In addition, they are able to preserve and protect the food for longer, minimizing the use of preservatives.

In relation to the consumer, they are easy to handle and open and offer an effective surface for printing labels or brands. However, although plastics are recyclable materials, they are pollutants.

In the plastic manufacturing process, there are many varieties of plastic resins, with the most used being:

Polyvinyl chloride (PVC): very resistant to humidity, fats and gases

Polyethylene and its varieties (PET, HDPE, LDPE). The development of the PET range has revolutionized the packaging industry, allowing plastic to compete directly with glass bottles.

Polystyrene (PS) is the plastic of choice for thermoforming due to its strength, malleability and low cost.

Metals (steel, tin, aluminum)

The main use of these metals is the preservation of canned foods and beverages. The most commonly used are tin-coated steel and aluminum cans. It is an opaque material that provides an advantage for food that is sensitive to light.

Tin cans are made of steel sheets coated with tin as a measure of protection against corrosion of steel.

Aluminum is increasingly used for canning due to its lightness, low cost and capacity to be recycled. It can be found in packaging, bottle closures, and wraps, and laminates. It has the same barrier properties as steel but with the advantage of being resistant to corrosion.

Aluminum foil is formed by layers of laminated aluminum. It is a highly flexible product that allows to preservation or protect food in the domestic environment. However, it is difficult to use in modern fast packaging equipment due to wrinkles, rips, and marks.

Thin-walled aluminum cans are suitable for carbonated beverages, while wide-walled cans are suitable for steam sterilization. Optionally, internal lacquers can be used to avoid interaction with the product and externally to protect the ink from the labeling.

Glass

Glass is an inert material that is impermeable to gases and vapors. It is an excellent and completely neutral oxygen barrier when in contact with food. However, it is a fragile, heavy material that requires a lot of energy to be manufactured.

Glass uses one of the most abundant raw materials on the planet, silica, but it is not renewable. Despite this, it is a recyclable product, since it can be used as a container repeatedly.

Glass containers can be bottles (the most used), jars, glasses, ampoules, jars, etc. However, this material is not used for frozen products due to the risk of breakage.

Types of food packaging:

Types of food packaging:

TRAYS AND PUNNETS

Relatively shallow containers that may have a lid. They are used as food containers. There are plastic trays of all kinds: those used as a primary food-contact packaging, such as foamed, transparent, high-barrier, peelable, and reclosable trays, and those used as secondary packages, which are normally thermoformed for containing other food packages.

Types of food packaging

BAG IN BOX

They are used for storing and transporting liquids. It is formed by an outer packaging, normally made of cardboard and an inner plastic bag. In many cases, the plastic bag incorporates a tap for dosing the product. It is widely used to package wine.

Types of food packaging:

JARS

Rigid containers consisting of a round neck with a diameter similar to that of the body diameter and with a relatively large opening capable of supporting a lid to keep the product inside. The section of the body is usually round or square

Types of food packaging

DOY-PACK

Flexible containers designed so that the base allows them to be held in an upright position both filled and empty. They usually incorporate two side longitudinal welds and another one in the upper part. In many cases, they have a mouthpiece to ration the product, closed with a cap.

Types of food packaging:

FILM

A continuous and thin layer of plastic material with a small thickness. When the thickness is higher than approximately 250 microns, we do not consider it a film, but a sheet.

Types of food packaging

FLOW-PACK

This packaging is formed by a film that has one longitudinal and two transverse welds and forms a perfectly sealed bag that contains the product.

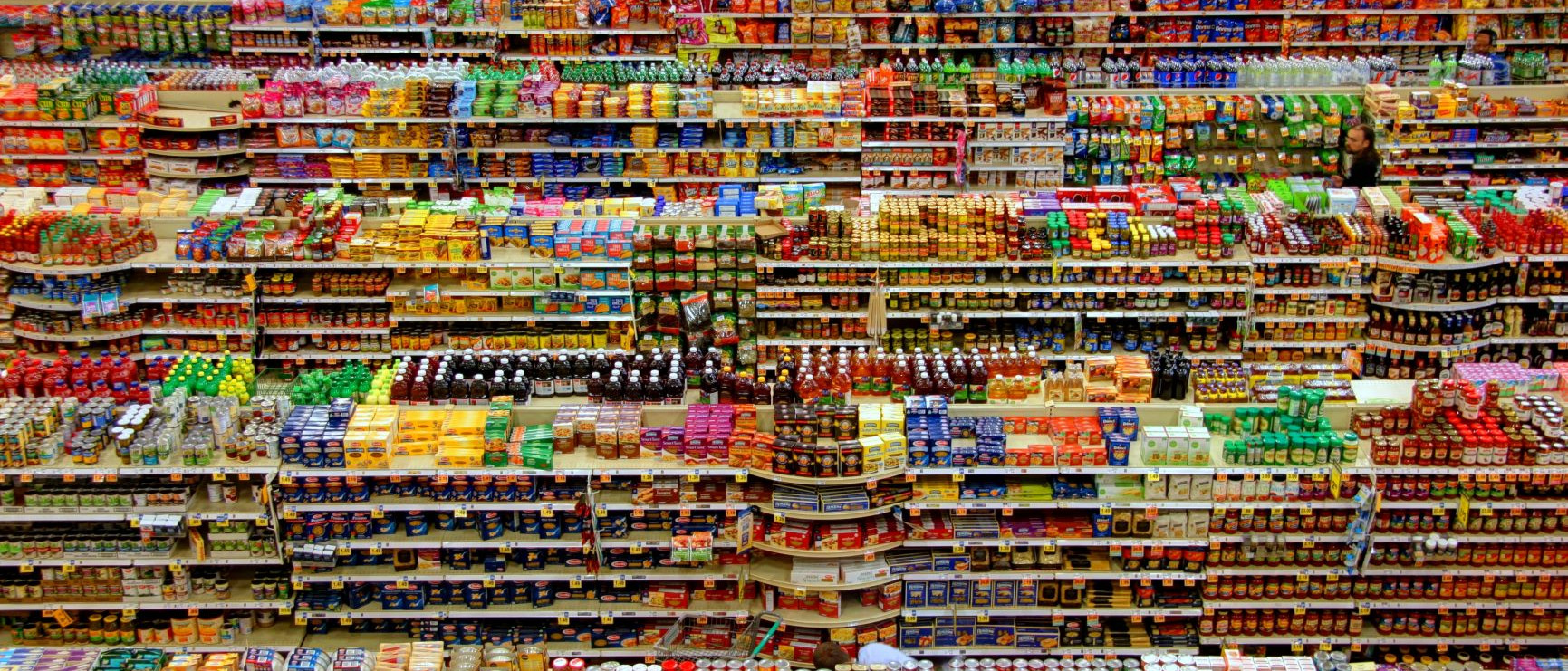

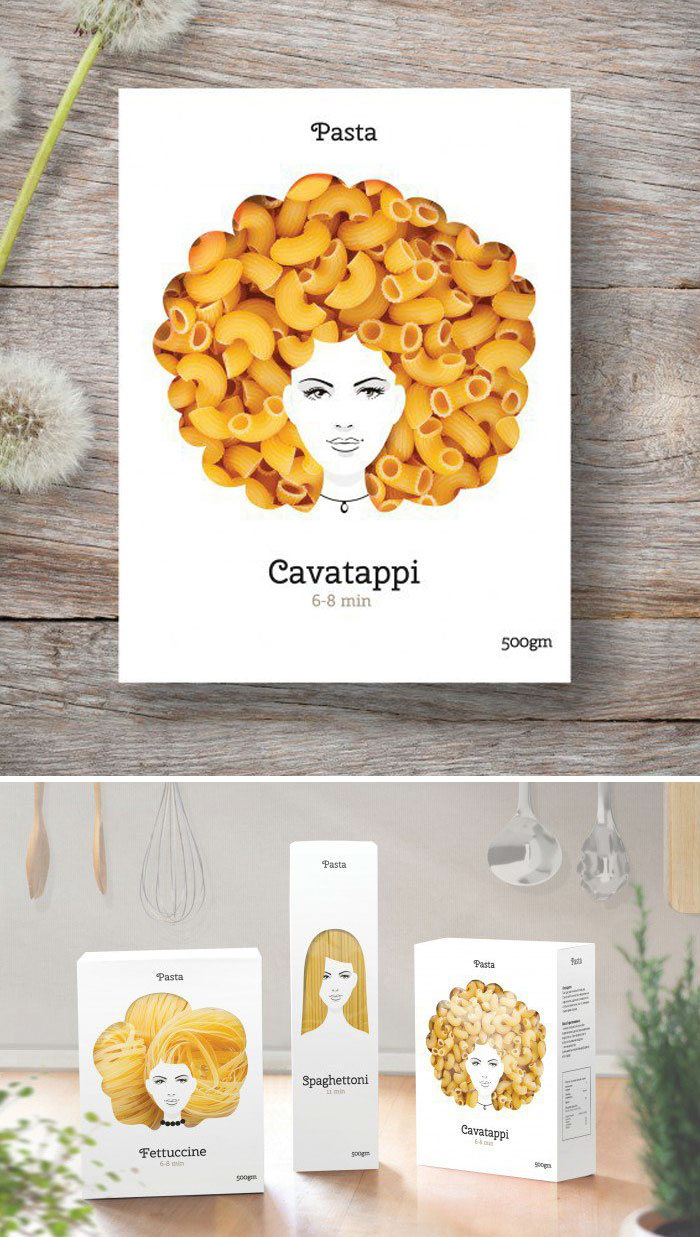

Inspiration packaging design in life

When you go to the supermarket, the most attractive product on the shelves is the packaging. Therefore, the unique packaging design is important. Here, we have collected a lot of special food packaging design for you, which one can inspire you?

With the increasing awareness of environmental protection, three major points of recyclable, degradable and recyclable will become the development trend of the packaging industry. So what is the green development prospect of food packaging?

Three Sustainability Trends Reshaping the Food Packaging Industry

Corporate leaders are embracing sustainable food and beverage packaging

A key food packaging trend in 2018 has been toward recycled and recyclable materials, partly in response to stunning media reports of waste plastic, notably the Great Pacific Garbage Patch (three times the size of France).

Beyond plastics, leading beverage and restaurant brands have answered the call and announced major sustainability-oriented commitments in 2018. The trend-setters include:

Coca Cola stated that by 2030 it will collect and recycle one bottle or can for each one it sells; and

McDonald’s announced a commitment to have 100% of its guest packaging made from renewable, recycled or certified sources by 2025.

These actions have pleased everyday consumers as well as committed environmentalists, and will have trickle-down effects, encouraging other companies to follow.

Governments are not only banning plastic, but mandating recycling and reusable materials

In Australia, national, state and territory environment ministers have agreed on an admirable target: 100% of Australian packaging is to be recyclable, compostable or reusable by 2025. This is only a few short years away, and a major opportunity for the food packaging industry.

The worldwide trend is clear on the legislative front: Less in the way of plastics and single use materials, more in the way of recycling and sustainable food packaging.

Innovative and sustainable food packaging is creating new solutions

Innovative recycled and recyclable food packaging materials are emerging as sustainable alternatives to plastics, Styrofoam and other environmentally-unfriendly materials. Such as Kraft paper packaging and pp woven bags currently used in the market.

Benefits of food packaging

In previous chapters the reasons why used food packaging has been described in detail. Here we have summarise several key poins of the benefits of food packaging! These benefits include:

– improved protection for the food and an increased shelf-life,

– better quality products reaching the consumer,

– more attractive products to compete with other manufacturers,

– easily identifiable products for consumers to select from retail shops,

– sometimes re-usable containers,

– tamperproof packages reduce the risk of adulteration,

– making foods more easily handled and stored by retailers and consumers,

– increased production output as a longer shelf-life enables a larger market to be found and year-round production possible.

Conclusion:

Consumers everywhere are increasingly looking at companies and brands to take the lead on environmental issues. And, as outlined above, the broad legislative trend toward bans and restrictions on unsustainable materials is encouraging the adoption of sustainable materials and practices.

For the food, beverage and restaurant industries, environmentally-friendly post-consumer recycled products can reduce environmental impact and contribute to the development of a truly sustainable economy, aligned trends.

Why choose PrimePac ?

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.