All You Want To Know About Cosmetic Packaging Material

Introduction

If you want to create a line of cosmetic products, there are many tasks you need to perform, such as making a list of ingredients, creating formulations, and then testing the product.

But the most important step is choosing the best packaging for your products.

The reason is that packaging is the first thing that catches the attention of potential customers.

And we know that it is very important to make a good impression on your customers and clients.

In this article, we’re going to talk about some common types of packaging materials you can use.

We believe that most of your problems with customers’ packaging can be solved after reading this blog.

Types of cosmetic packaging

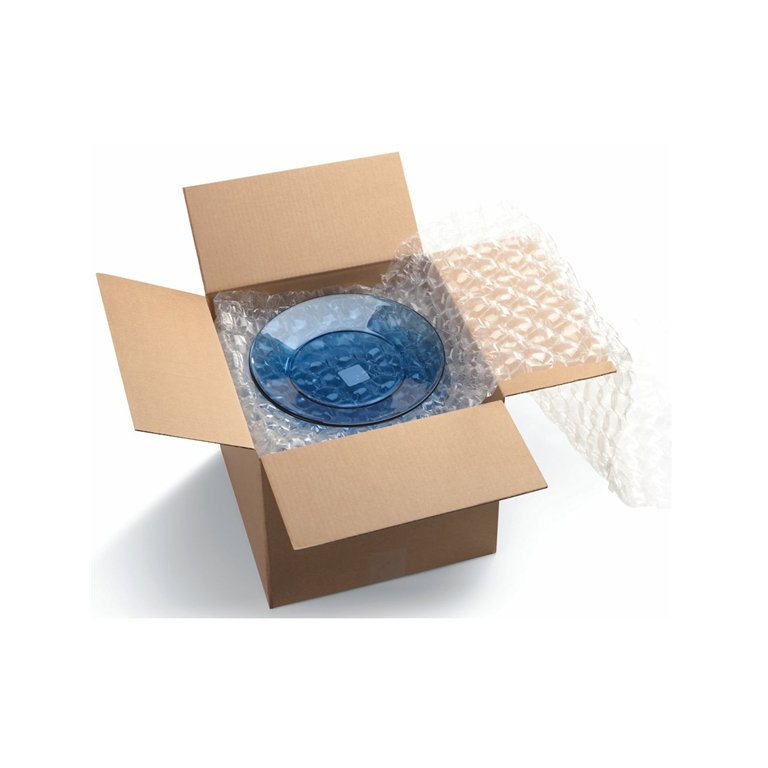

When it comes to packaging, we also think of three different layers: the outer packaging, the inner packaging, and the product packaging.

The outer packaging

The outer packaging is The shipping box or mailer box in which your cosmetic products are packed to be delivered or the bag in which they are packed at the checkout In a shop

For shopping online, the first thing your customers will Access is your outer packaging, such as shipping boxes, mailer boxes, and so on.

The inner packaging

boxes your customers open to get their lipstick or cream jar.

Different cosmetic packaging materials

Glass

Glass is the safest material for cosmetic products.

This material is an ideal choice for products that contain different types of oils and acids.

As glass is not affected by corrosion, it can stand the test of time.

Glass is also easily recyclable.

The advantages of glass

On the good side, glass is generally considered the most “natural” of the lot, both in terms of its production (low pollution) and its composition.

Indeed, the manufacture of one ton of glass requires about 700 kilos of sand, 200 kilos of limestone, and 300 kilos of various raw materials.

All these materials are found in abundance in nature

In addition, it gives the product an elegant, even luxurious touch. For example, thick-walled glass jars are often used for creams, balms, and also eyeshadows, lip glosses, and gels.

Glass bottles and flasks are the norms for essential oils and vegetable oils.

Besides, tinted glass (amber or blue) is preferred so that the contents are protected from light and do not deteriorate.

Being easy to clean, even at high temperatures, glass containers are easily reused.

Glass is also easily recyclable. Throwing a glass jar or bottle into the waste garbage can has become a well-established habit for most consumers.

The disadvantages of glass

On the downside, glass is obviously a heavy and fragile material, so its eco-balance (transport and logistics) is greater than with plastic or metal.

It is also quite energy-consuming since the melting necessary for its manufacture implies reaching about 1500°C, at a rate of more than 1160 kWh /tonne of glass produced.

3. Plastic

It is light, flexible, unbreakable, and hygienic, not to mention its low cost.

From an aesthetic point of view, plastics are also extremely flexible and can therefore adopt a wide variety of shapes and colors.

The plastics industry is also renewing itself to offer more and more recycled plastic containers.

It is also important to understand that not all plastics are created equal.

As such, we recommend these two types: PET (polyethylene terephthalate – number 1), and PP (polypropylene – number 5);

The latter is preferred because of its higher recycling rate.

We should also mention the recent appearance of PET bio-plastics, made from sugar cane.

Their use is still rare, but they should be of interest to many manufacturers in the future…

A PET container shipped 1,000 km away saves 19g of CO2 (carbon dioxide equivalent) compared to the same glass container.

The advantages of plastic

It is obviously its low cost that makes it the market leader.

It is also light, flexible, unbreakable, and hygienic.

From an aesthetic point of view, plastics are also extremely flexible and can therefore be made in a wide variety of shapes and colors.

Since the end of the 2010s, the plastics industry is also renewing itself to offer more and more containers made of recycled plastics, a good point that shows the evolution of the sector. But can this be enough?

The disadvantages of plastic

In addition to the environmental problems of the oil from which this material is derived, a drawback of plastic is its physical stability.

It is vulnerable to absorption, stress cracking, and cracking. Its poor resistance to ink and other chemicals also limits its use for certain types of packaging.

Some plastics used in the food industry have recently been suspected of releasing toxic substances (bisphenols, phthalates…) under certain conditions of use (e.g. microwave cooking).

These phenomena of interactions between the container and the content can potentially have an impact on the quality, effectiveness, and safety of a cosmetic product.

However, they are not yet sufficiently studied in the cosmetics sector.

Moreover, plastic is not infinitely recyclable. It ends up either rejected in nature in some form or burned in sorting centers.

And there is a problem of energy consumption and potentially toxic emissions into the environment.

PET

Polyethylene terephthalate looks like glass. But in reality, it is clear plastic bottles or jars. In most cases, it is used for beverages and cosmetics.

Over the years, they have gained popularity because they are unbreakable, inexpensive, and lightweight.

PET is one of the best cosmetic containers because it creates a solid barrier between the product and the solution it contains.

Thus, the material does not react with the plastic. PET is a perfect choice if you want to store essential oils and alcohol.

PP

Propylene plastic is also known as PP, which is another popular packaging solution for cosmetic and skincare brands.

When it comes to strength, it’s better than PET. Some examples of these units include deodorant tubes, square lotion tubes, and hand cream jars, to name a few.

HDPE

HDPE, or high-density polyethylene, is a popular material choice for cosmetic packaging due to its durability and resistance to wear and tear.

HDPE is versatile in that it can be molded into a wide range of shapes and sizes, making it ideal for accommodating a variety of products and applications.

Additionally, HDPE is fully recyclable, making it a sustainable material choice for eco-conscious consumers.

When selecting HDPE for your cosmetic packaging needs, be sure to consider the weight and contents of your product to ensure that the material can properly support and protect your product.

The Application of Plastics Materials in Cosmetic Packaging

At present, the application of barrier packaging materials in cosmetic packaging is in a period of increasing use.

Commonly used domestic high-barrier materials include aluminum foil, polyvinyl alcohol (PVA), ethylene-vinyl alcohol copolymer (EVOH), nylon (PA), and polyethylene terephthalate (PET), etc. Aluminum foil, PVA, and EVOH are high-barrier materials.

Nylon, PVA, and EVOH have similar barrier properties and are medium barrier materials.

For cosmetic tube packaging products, if the product itself has high barrier properties, the following three types of barrier plastic pipes are generally used.

ABL

its typical structure is PE/PE+EAA/AL/PE+EAA/PE, which is made of aluminum foil and plastic film by co-extrusion and compounded into sheets and then into pipes. The main barrier is The barrier property of the aluminum foil layer mainly depends on the degree of the pinhole of aluminum foil. When the thickness of the aluminum foil increases, the barrier property increases ;

PBL

its typical structure is PE/PE/EVOH/PE/PE, all plastic compounds, and its barrier layer is usually EVOH or oxidized PET. As the thickness of EVOH increases, the barrier is strengthened;

Get more information about ABL and PBL, you can read this blog:

ABL vs. PBL vs. Co-Extruded Tubes: What’s Right For You

3. Aluminum

Metal cosmetic containers are most often made of aluminum, as shown by our hairspray, deodorant, shaving foam, or toothpaste.

As a barrier material, aluminum offers excellent protection against germs, UV, humidity, and temperature variations.

Aluminum bottles are therefore particularly suitable for fragile contents, being able to dissipate heat.

The advantages of aluminum

As a barrier material, aluminum offers excellent protection against germs, UV, humidity, and temperature variations.

By dissipating heat, aluminum bottles are particularly suitable for fragile contents.

Typical example: is hydrolats, whose fragrances and virtues can then be preserved.

Another advantage is that metal packaging is unbreakable and infinitely recyclable.

For companies wishing to be environmentally friendly, aluminum is an excellent choice.

It saves natural resources, even though aluminum is the most abundant metal on earth.

Particularly positive is the fact that about half of the aluminum used by industry in Australia is recycled aluminum.

Much lighter and more malleable than glass, aluminum can be shaped into a wide variety of shapes and sizes. It offers manufacturers many exclusive design possibilities, and its silvery sheen gives it a certain elegance.

The disadvantages of aluminum

The production of aluminum causes air pollution and toxic waste during the extraction and processing of the metal (e.g. red mud).

And from a practical point of view, aluminum dents at the slightest impact.

Finally, aluminum has recently criticized when it was introduced into cosmetic formulas themselves.

It is suspected of being neurotoxic and present in some deodorants and toothpaste.

But aluminum cosmetic containers are not concerned because a food-grade interior varnish always separates the container from the content, thus avoiding any risk of migration.

Glass Or Plastic: Which Pollutes More?

If we take into account only the basic material intensity figures (ratio between the domestic consumption of raw materials and the gross domestic product), a jar made of PET (a thermoplastic polymer) uses twice as much abiotic material (minerals and fossil fuels) and 17 times as much water (needed in its manufacturing process) as a similar jar made of glass.

To obtain 1 kilo of PET plastic, 2 kilos of oil are needed.

Thus, the amount of greenhouse gas emissions is 5 times higher for the plastic jar. In this respect, glass is the clear winner.

But beware: this result is only valid in a local system, where the pollution caused by the transport of the product is negligible.

Over long distances, the material intensity figures are multiplied by the number of kilometers traveled to transport the glass.

In this case, the glass loses out because it requires five times as much transportation due to its weight.

A PET jar shipped 1000 km away saves 19g of CO2 (carbon dioxide equivalent) compared to a glass jar.

In addition, plastics recycling is progressing.

PET is often recycled, at least in part, and can be incinerated to produce fuel.

PP (Polypropylene) plastic is even more environmentally friendly: it is just as light and fully recyclable since it can be sorted with recyclable plastics.

Cellulosic materials

We can’t talk about packaging without talking about cellulosic material, that is to say, any packaging made of wood, paper, or cardboard. Boxes, POP displays, cartons, and trays are generally designed with cellulosic materials.

Many industries are turning to these packaging solutions: food, cosmetics, fashion…

Advantages of Cellulosic Materials

Cellulosic materials are biodegradable, easily recyclable or reusable, and inexpensive.

Paper or cardboard packaging has the advantage of supporting several printing methods and offers a wide variety of renderings.

Colors, patterns, and finishes stand out very well on this type of support.

The manufacturers dissociate two types of cardboards: flat or compact and corrugated.

The corrugated cardboard is composed of one or more sheets of fluted paper.

It is often used for packages or packaging of fragile or heavy products.

Light and not very cumbersome, cellulose materials have the advantage of being able to be stored flat during transport.

It is, therefore, possible to transport large quantities.

The disadvantage of cellulosic materials

Even if cellulosic materials seem to be a miracle solution to the environmental crisis, this idea must be qualified.

Indeed, it can often be difficult to recycle cellulosic fiber packaging covered with ink or varnish because these finishes can hinder its recyclability.

Just because you use cardboard for your packaging doesn’t mean you have a lower environmental impact!

Besides they are sensitive to humidity and are less resistant or impermeable than glass or steel.

Conclusion

So what is the best type of packaging for cosmetics?

The answer to that question depends on a variety of factors, including Your packaging needs, budget, environmental elements, and so on.

In Primepac, we’ll provide packaging solutions that can fit your products based on your requirements.

Please feel free to contact us and let us help with your packaging.

However, plastic is cheaper to produce and easier to recycle.

Ultimately, it’s up to the cosmetic company to decide what material they want to use based on their specific needs and priorities.

We hope this article has given you a better understanding of the different types of cosmetic packaging materials available today.

Still, have any questions? Please feel free to contact us!