Truth about the vacuum packaging you may want to know !

Talk about vacuum bag packaging

Vacuum packing or vacuum packaging is a form of modified atmosphere packaging found around the world. Vacuum packing removes atmospheric oxygen from the primary package products are enclosed in. Oxygen is the primary source of product degradation. The removal of oxygen can often extensively help extend product life. Consumable and non-consumable products are protected by vacuum packing.

The basic form of vacuum packing removes oxygen from a vacuum bag and seals off the bag once a vacuum cycle is complete.

Vacuum packaging does have its problems. No one is perfect. Unfortunately, vacuum packaging is currently not as easy to recycle as other types of packaging.

That said, as the global population stabilizes but continues to grow, estimated to reach around 10 billion by 2050, we need to urgently address ways to provide those numbers. Ultimately, the amount of waste is unsustainable, and smarter, more efficient ways of packaging food will allow us to begin the fight against malnutrition and sustainability in the food industry.

Though early experiments of modified atmosphere packaging have been traced back to the early 19th century, most accounts of vacuum packaging are not acknowledged until after World War II. In France before WW II, the air was removed from rubber latex bags, and the bags were sealed. This concept proved to increase the shelf life of frozen products.

The Cryovac vacuum packaging process created in the 50s to package whole turkeys was the first commercial use of vacuum packaging perishable items. Since the introduction of industrial vacuum packaging, many companies and individuals have contributed new methods, materials, and machines that have improved the quality of human life.

By the 70s, the idea of introducing an inert gas into vacuum packaging helped to increase the shelf life of perishable products dramatically. Since then, the advancements in vacuum packing efficiency and increased shelf life have made incredible advancements.

Now it’s seem you have a basic know of vacuum packaging, let’s see the types of vacuum bags packaging we commonly use in our life.

Types of vacuum bags packaging

1.Side seal bags

Side seal bags are ideal for storing in foods while retaining freshness and aroma, for maturing food products or attractively displaying them on the shelf. PrimePac produces the three-edged vacuum bags made of high-quality PA/PE barrier film in numerous formats. The PA (polyamide) provides an oxygen barrier and aroma protection, while PE (polyethylene) ensures a moisture barrier and optimal sealing properties.

Types of vacuum bags packaging

2.Tubular bags

All products demand an impeccable appearance. We recommend tubular bags without side seams, which cling closely to the products, showing off their contours to their best advantage. These bag types are manufactured from high-quality PA/PE composite films which feature an excellent oxygen barrier, high transparency, and puncture resistance as well as outstanding sealing properties.

Types of vacuum bags packaging

3.Shrink bags

The ASB shrink bag (PVDC) or our ASBC shrink bags with EVOH barrier extend the shelf life of the products with an almost “invisible” packaging. The special film structure and selected high barrier materials ensure high puncture resistance, low air-penetration rates and long-lasting protection.

Types of vacuum bags packaging

4.Cook-in bags

They withstand any temperature without delamination, leaking, flex-cracking or streaking. The temperature resistance of -40°C to +121°C allows gentle cooking in the Sous-Vide process, making them a must-have in every canteen kitchen. Cook-in bags with a tolerance of up to 121°C can also be used for sterilisation.

VACUUM PACKAGING COMMONLY USED IN LIFE

OVER PURCHASES OR BUY-INS

Preserve quality and extend shelf life or stored raw foods-meats, dairy, vegetables, fruits.

OVER PRODUCTION

Preserve cooked food without exposure to air or dehydration.

MEATS

Portion and re-package for assured shelf life. Store (refrigerated or frozen) and preserve quality of prime items for future use.

SMOKED MEATS

Most smoked products contain a percentage of water.Vacuum Packaging prevents moisture evaporation (yield loss) plus provides an attractive temper resistant package.

VEGETABLES

Portion pack “in-season” product and refrigerate for later preparation. Re-package bulk quantities for menu rotation. Maintain salad freshness and crispness.

SANITATION

Prevents cross-contamination of flavours and aromas. It also prevents yield loss of products (i.e. blood, water).

CHEESE

Prevents drying, crumbling and mold of bulk and grated. Eliminates the labour cost of trimming and rewraps.

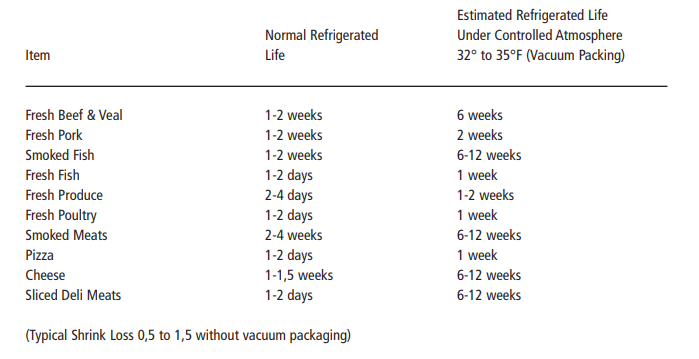

Typical shelf lives of vacuum packaged :

All vacuum packaged foods must be top quality, fresh and prepared in a sanitary method in order to reach optimum shelf life. In addition, shelf life can be affected by acidity, pH level, temperature and ingredients.

Some typical shelf lives of vacuum packaged refrigerated products, as compared to normal refrigeration, are:

The above shelf lives may vary and can be affected by product freshness, acidity, pH level, temperature, ingredients, sanitation and laminates used in pouch construction.

Previously we mentioned the application of vacuum bags packaging in our daily life, you may confuse about why there is everywhere using vacuum bags packaging? What are some special advantages of Vacuum Packaging? Thus, we list several FAQs about vacuum packaging, also the advantage introduction about using vacuum bags packaging as well.

Let’s see!

Q: Do Vacuum Packaged products still need to be refrigerated?

A: Yes. Some organisms are resistant to high carbon dioxide levels. Their growth is slowed at lower temperatures

Q: What are some special advantages of Vacuum Packaging?

A: Only a sampling of the advantages include:

- Vacuum packaging reduces product shrinkage. There is no moisture loss or evaporation in sealed vacuum bag. Therefore, the weight you package will be the weight you sell.

- Vacuum packaging reduces trim losses by eliminating oxidation and freezer burn.

- Vacuum packaging can enhance product quality. Vacuum packaged meat held at 32° to 35°Fdoes not hinder “aging” or tenderising.

- Vacuum packaging allows more efficient use of time. Food can be prepared in advance without loss of freshness, so slack times are more productive and busy times are more manageable.

- Vacuum Packaging allows for money saving quantity buying. Products such as cheese, continental small goods, fish, bacon, coffee and nuts, processed meats and many other food items may be bought in bulk at a lower price and then pre-packaged by either a central warehouse or in each supermarket or restaurant outlet.

8 Vacuum Packaging Benefits You Should Know !

- Increased Shelf Life – Studies have shown that vacuum packaging can increase product shelf life from 50%-400%. Vacuum Packaged SalmonThe key to increasing product shelf life is determining the ideal atmosphere within the packaging for the product being packaged. This could be the introduction of inert gas or the reduction of oxygen to ideal levels. Vacuum packaging is also and preferred form of packaging for many products going into long term freezer storage. The proper vacuum bags can dramatically reduce freezer burn. It is a chosen form of packaging for meat storage around the world.

- Reduced Product Loss – Increased shelf life directly affects the reduction in product loss for companies inventorying products. The reduced product loss helps to increase bottom lines.

- Sealed Barrier From External Elements – The most common vacuum bag thickness is a 3 mil thickness with some Vacuum Packaged Dried Fruit bags up to a 6-8 mil thickness. With the proper seal, vacuum packaging can protect products from dust, moisture, insects, and a variety of other external elements that may harm or damage products. Vacuum packaging is also an excellent barrier of protection against freezer burn during long term freezer storage.

- Seals in Flavors – Wet aging meats is a popular form of curing meat before preparing it. This often uses natural juices from the meat with spices and flavours vacuum sealed to lock in flavours during the curing process.

- No Chemical Preservatives Required – Vacuum packaging eliminates the need for chemical preservatives. With the right mixture of oxygen to inert gas, products can last longer without the use of commonly used preservatives. The earth’s atmosphere is made up of 78% nitrogen which is the most commonly used inert gas for vacuum packaging.

- Improved Product Presentation – Most vacuum bags are crystal clear allowing products within the packaging to be displayed on shelves. Vacuum packaging is an affordable packaging solution the enables products to be shelf-ready Vacuum Packaged Dried Tomatoes with the application of a custom printed sticker.

- Multiple Packaging Options – Vacuum sealing materials come with multiple packaging options. Users can buy rolls of film or bags to seal products. Bags can be found with reclosable zippers, easy-open tear notches, foil-lined, channeled, and with a variety of other options to choose from.

- Quick and Efficient Packaging – With the proper machines and materials, vacuum sealing can be a very efficient process enabling hundreds or thousands of products to be sealed per hour.

Conclusion:

Now, we see the vacuum packaging not only provides a clean and hygienic packaging method for food, but also do help to saves the space. It is an indispensable packaging for the industry!

Therefore, choosing the right packaging method can improve the effectively of the product. Similarly, choosing a reliable packaging manufacturers is also an important thing!

About PeimePac

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

Network

With our team in China and Australia working as one, we reduce inefficiency so that you deal with one streamlined team from manufacturing right to delivery.

Service support team located in Guangzhou, the manufacturing hub of China, providing rapid response, and local industry knowledge. Warehouse and 3PL net work located in Sydney, to provide rapid distribution, and delivery to your customers.

Food packaging - Your 2020 complete guide

Food packaging is an integral part of food commodities. One of the major projects in the food industry process. It protects food and prevents the damage of biological, chemical, and physical external factors during the circulation of food from the factory to the hands of consumers. It also has the function of maintaining the stable quality of the food itself, and it is convenient for food consumption. It is the first to express the appearance of food and attract consumers. It has value beyond material costs. Therefore, the food packaging process is also an integral part of the food manufacturing system engineering.

Food packaging plays an important role in the industry, also it’s an indispensable presence in our life. Nowadays, more and more consumers choose green products. Thus, is undoubtedly an industry innovation for food packaging. From production standards to use standards, manufacturers have begun to focus on the development direction of eco-friendly protection and recycling technological innovation.

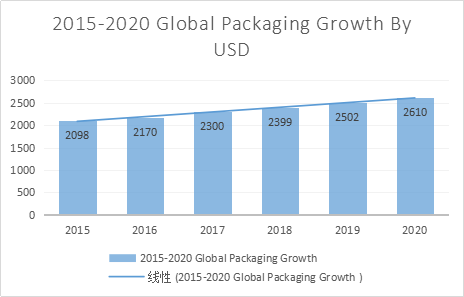

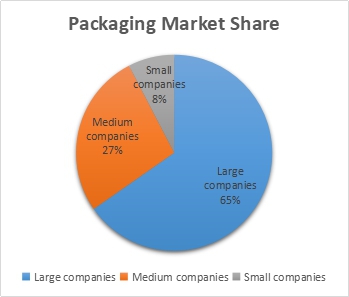

Let’s see the development of food packaging and the subsequent market situation! In order to boost your business, here are some key points you have to know about the food packaging industry!

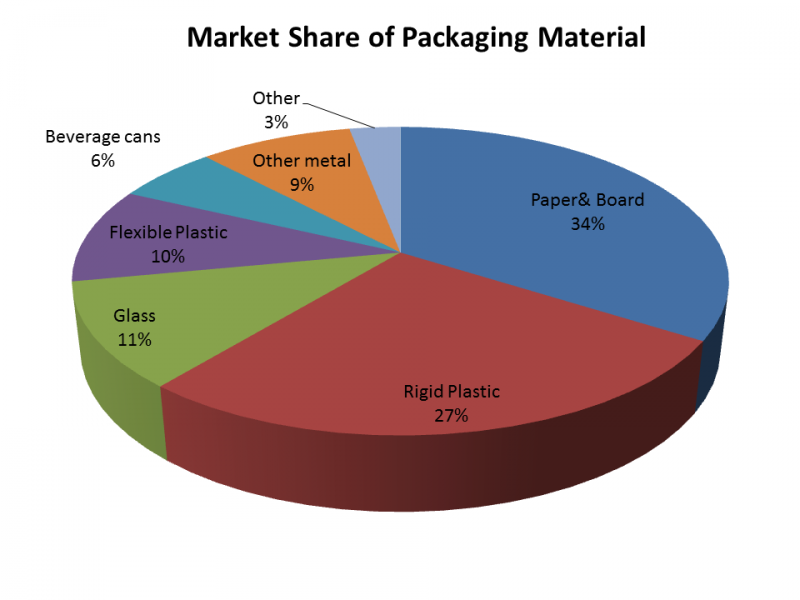

Food packaging situation right now:

For some types of food packaging, the food contact material determines the name. A plastic bottle is made of plastic and has this material type in direct contact with the foodstuff. For glass jars, the materials in contact with the foodstuff are glass and coated metal from the closure.

In the case of beverage cartons, the direct food contact layer is not a carton, but laminated plastic. For aluminum cans, a coating is in direct contact with the beverage. Some types of paper can also be coated (for example with a grease-proof coating).

What are the requirements of food packaging in Australia?

If you're a food business, it's important to know what types of packaging are safe to use with your food products.

Under Standard 3.2.2 – Food Safety Practices and General Requirements, food businesses must:

- Only use packaging material that is fit for its intended purpose.

- Only use a material that is not likely to cause food contamination.

- Ensure there is no likelihood that the food may become contaminated during the packaging process.

Access the Food Packaging Infobite as a PDF here:

Food packaging is widely used in our life. You may also know a lot about the materials and types of food packaging. Let’s see how to choose food packaging materials that can also reduce pollution and maintain your health.

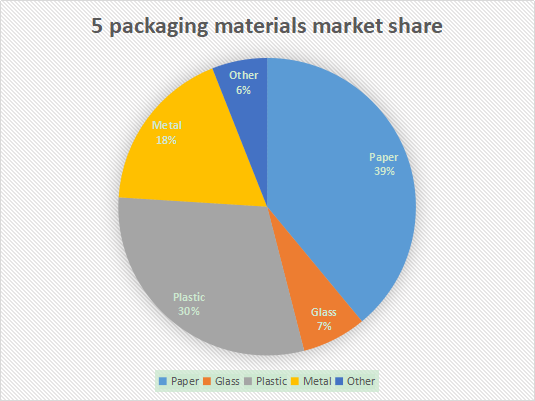

Types of packaging material used in food :

The most used materials in the food industry are detailed: plastics, glass, metals, and wood and its derivatives.

Wood, cardboard, and papers:

Products derived from wood are widely used in the packaging of food in the form of paper and cardboard. Paper is a very cheap, lightweight product with excellent printing capacity. Although it is very sensitive to moisture, it can be corrected with a combination of paper and other materials such as plastic or paraffin.

Cardboard is a material made up of several superimposed layers of paper, making it thicker, harder, and more resistant than paper. Its main use is for packaging and containers in the form of boxes.

In recent years, paper and packaging manufacturers are paying special attention to issues related to health and the environment by working with recycled products that increase the useful life of these raw materials. Therefore, some manufacturers try to used kraft paper packaging as one of the food packaging.

Plastics

Plastics are organic polymeric materials that can be molded into the desired shape. The lightness and versatility of these have been confirmed over decades in the processing and packaging of food. Plastic containers and packaging protect against the contamination of food and offer adequate mechanical strength.

Due to a lower cost and lower energy consumption during manufacturing, plastics have replaced traditional packaging materials. In addition, they are able to preserve and protect the food for longer, minimizing the use of preservatives.

In relation to the consumer, they are easy to handle and open and offer an effective surface for printing labels or brands. However, although plastics are recyclable materials, they are pollutants.

In the plastic manufacturing process, there are many varieties of plastic resins, with the most used being:

Polyvinyl chloride (PVC): very resistant to humidity, fats and gases

Polyethylene and its varieties (PET, HDPE, LDPE). The development of the PET range has revolutionized the packaging industry, allowing plastic to compete directly with glass bottles.

Polystyrene (PS) is the plastic of choice for thermoforming due to its strength, malleability and low cost.

Metals (steel, tin, aluminum)

The main use of these metals is the preservation of canned foods and beverages. The most commonly used are tin-coated steel and aluminum cans. It is an opaque material that provides an advantage for food that is sensitive to light.

Tin cans are made of steel sheets coated with tin as a measure of protection against corrosion of steel.

Aluminum is increasingly used for canning due to its lightness, low cost and capacity to be recycled. It can be found in packaging, bottle closures, and wraps, and laminates. It has the same barrier properties as steel but with the advantage of being resistant to corrosion.

Aluminum foil is formed by layers of laminated aluminum. It is a highly flexible product that allows to preservation or protect food in the domestic environment. However, it is difficult to use in modern fast packaging equipment due to wrinkles, rips, and marks.

Thin-walled aluminum cans are suitable for carbonated beverages, while wide-walled cans are suitable for steam sterilization. Optionally, internal lacquers can be used to avoid interaction with the product and externally to protect the ink from the labeling.

Glass

Glass is an inert material that is impermeable to gases and vapors. It is an excellent and completely neutral oxygen barrier when in contact with food. However, it is a fragile, heavy material that requires a lot of energy to be manufactured.

Glass uses one of the most abundant raw materials on the planet, silica, but it is not renewable. Despite this, it is a recyclable product, since it can be used as a container repeatedly.

Glass containers can be bottles (the most used), jars, glasses, ampoules, jars, etc. However, this material is not used for frozen products due to the risk of breakage.

Types of food packaging:

Types of food packaging:

TRAYS AND PUNNETS

Relatively shallow containers that may have a lid. They are used as food containers. There are plastic trays of all kinds: those used as a primary food-contact packaging, such as foamed, transparent, high-barrier, peelable, and reclosable trays, and those used as secondary packages, which are normally thermoformed for containing other food packages.

Types of food packaging

BAG IN BOX

They are used for storing and transporting liquids. It is formed by an outer packaging, normally made of cardboard and an inner plastic bag. In many cases, the plastic bag incorporates a tap for dosing the product. It is widely used to package wine.

Types of food packaging:

JARS

Rigid containers consisting of a round neck with a diameter similar to that of the body diameter and with a relatively large opening capable of supporting a lid to keep the product inside. The section of the body is usually round or square

Types of food packaging

DOY-PACK

Flexible containers designed so that the base allows them to be held in an upright position both filled and empty. They usually incorporate two side longitudinal welds and another one in the upper part. In many cases, they have a mouthpiece to ration the product, closed with a cap.

Types of food packaging:

FILM

A continuous and thin layer of plastic material with a small thickness. When the thickness is higher than approximately 250 microns, we do not consider it a film, but a sheet.

Types of food packaging

FLOW-PACK

This packaging is formed by a film that has one longitudinal and two transverse welds and forms a perfectly sealed bag that contains the product.

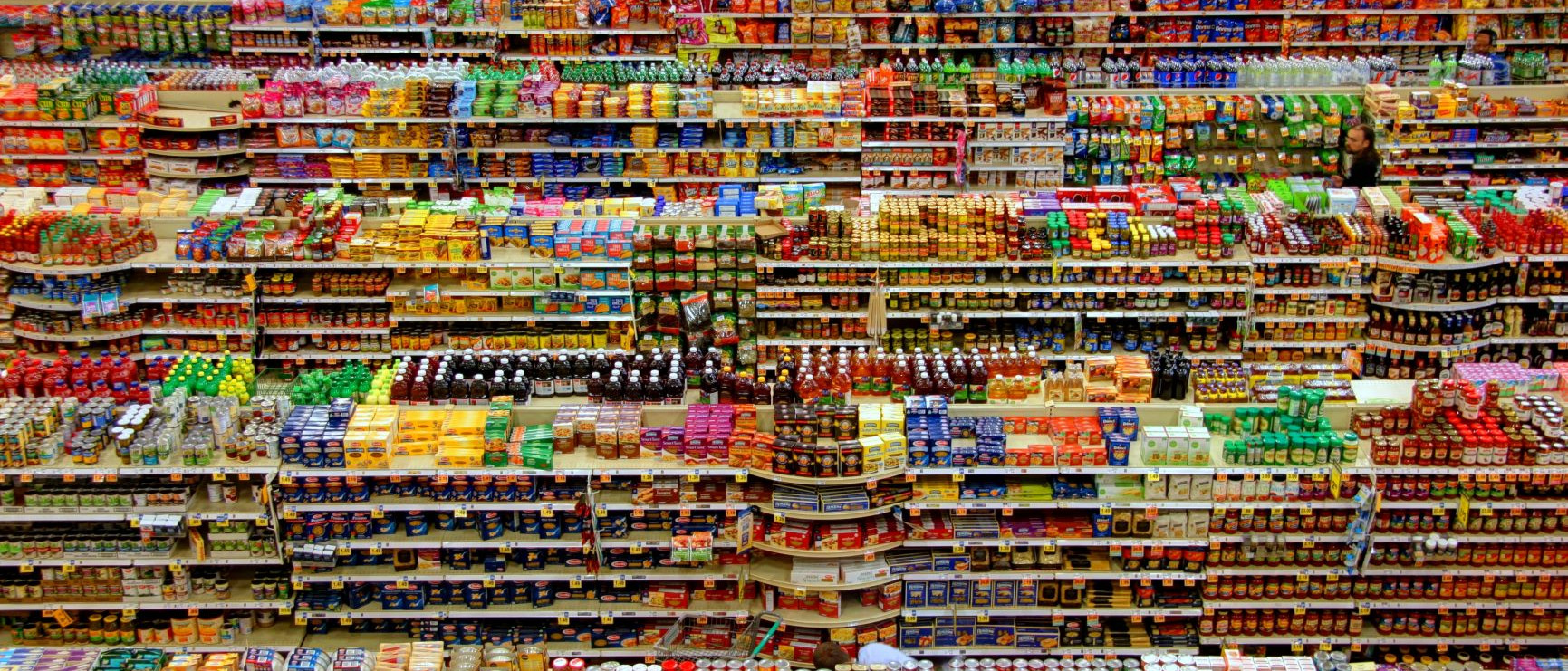

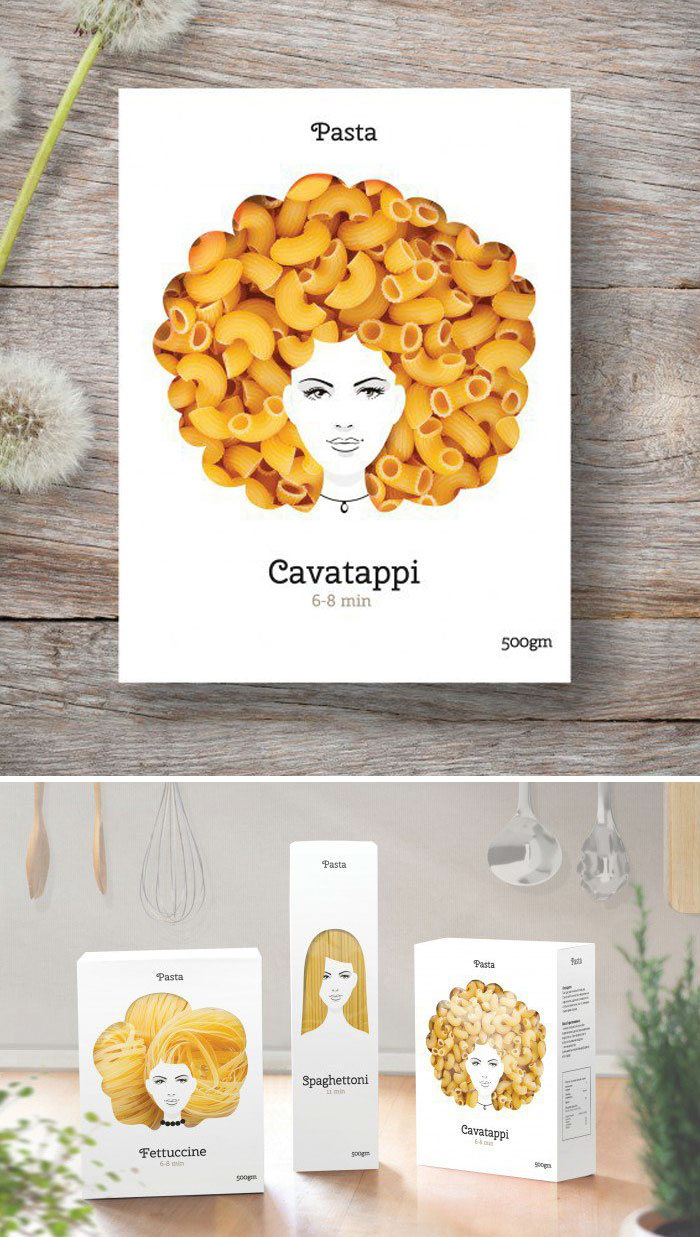

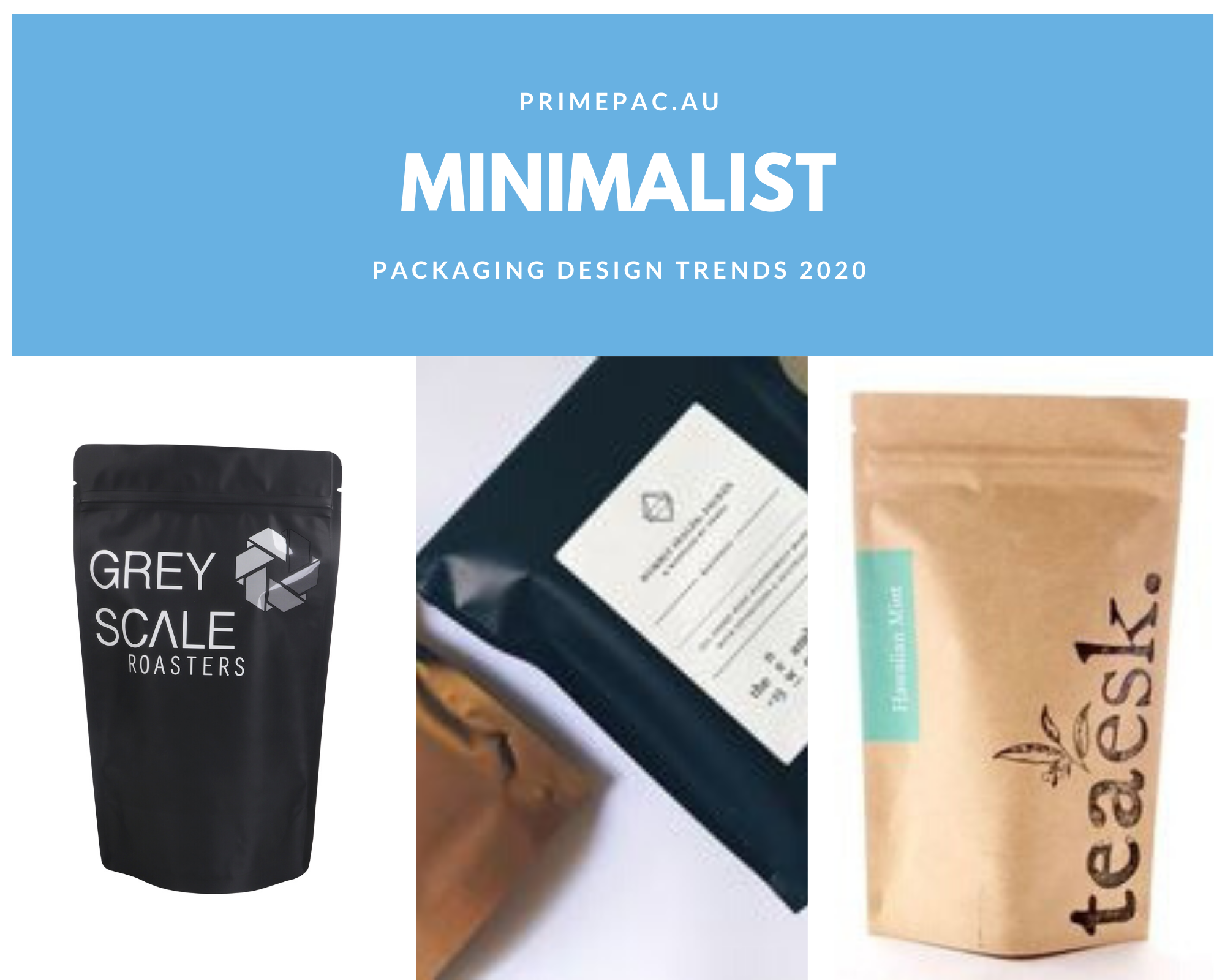

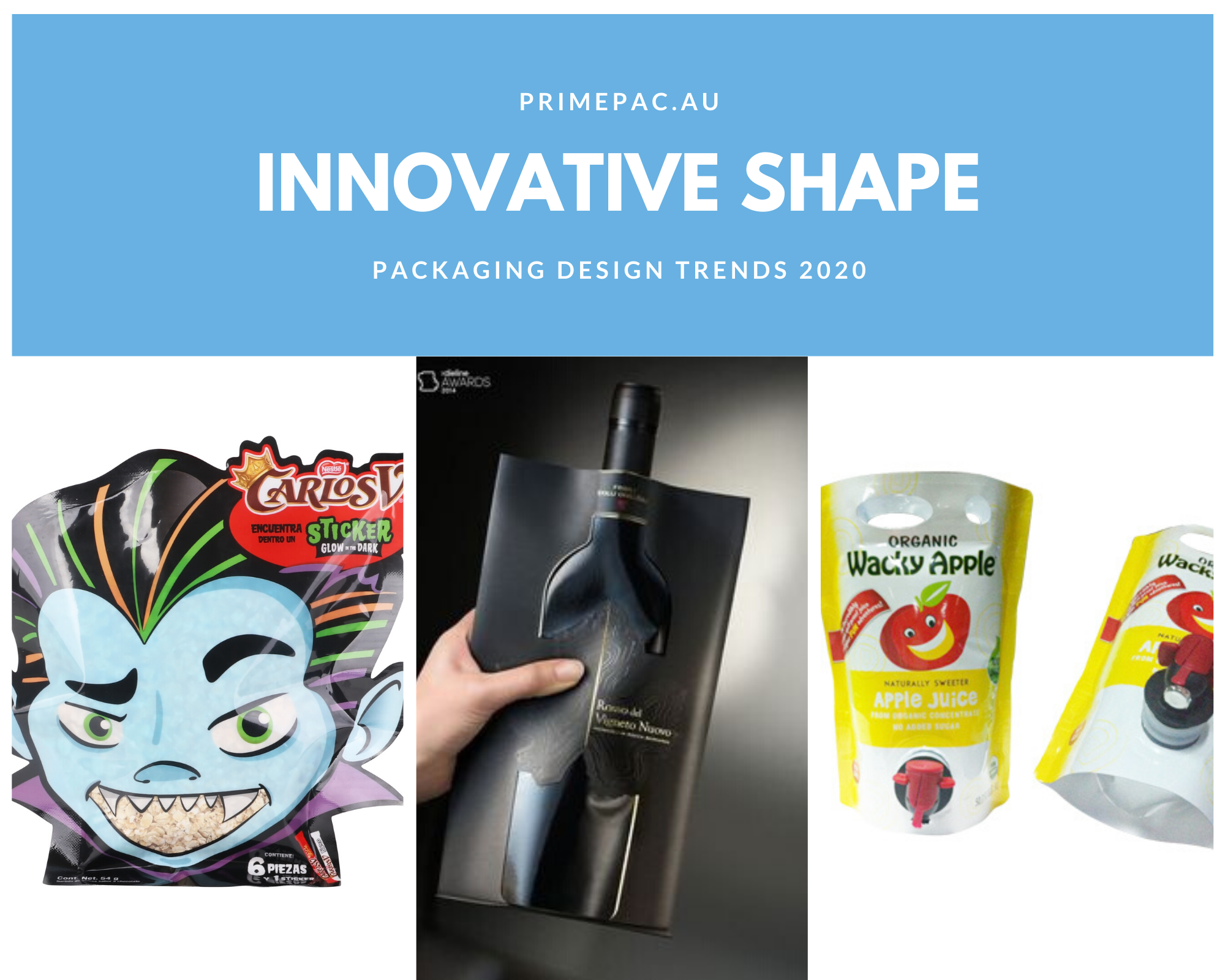

Inspiration packaging design in life

When you go to the supermarket, the most attractive product on the shelves is the packaging. Therefore, the unique packaging design is important. Here, we have collected a lot of special food packaging design for you, which one can inspire you?

With the increasing awareness of environmental protection, three major points of recyclable, degradable and recyclable will become the development trend of the packaging industry. So what is the green development prospect of food packaging?

Three Sustainability Trends Reshaping the Food Packaging Industry

Corporate leaders are embracing sustainable food and beverage packaging

A key food packaging trend in 2018 has been toward recycled and recyclable materials, partly in response to stunning media reports of waste plastic, notably the Great Pacific Garbage Patch (three times the size of France).

Beyond plastics, leading beverage and restaurant brands have answered the call and announced major sustainability-oriented commitments in 2018. The trend-setters include:

Coca Cola stated that by 2030 it will collect and recycle one bottle or can for each one it sells; and

McDonald’s announced a commitment to have 100% of its guest packaging made from renewable, recycled or certified sources by 2025.

These actions have pleased everyday consumers as well as committed environmentalists, and will have trickle-down effects, encouraging other companies to follow.

Governments are not only banning plastic, but mandating recycling and reusable materials

In Australia, national, state and territory environment ministers have agreed on an admirable target: 100% of Australian packaging is to be recyclable, compostable or reusable by 2025. This is only a few short years away, and a major opportunity for the food packaging industry.

The worldwide trend is clear on the legislative front: Less in the way of plastics and single use materials, more in the way of recycling and sustainable food packaging.

Innovative and sustainable food packaging is creating new solutions

Innovative recycled and recyclable food packaging materials are emerging as sustainable alternatives to plastics, Styrofoam and other environmentally-unfriendly materials. Such as Kraft paper packaging and pp woven bags currently used in the market.

Benefits of food packaging

In previous chapters the reasons why used food packaging has been described in detail. Here we have summarise several key poins of the benefits of food packaging! These benefits include:

– improved protection for the food and an increased shelf-life,

– better quality products reaching the consumer,

– more attractive products to compete with other manufacturers,

– easily identifiable products for consumers to select from retail shops,

– sometimes re-usable containers,

– tamperproof packages reduce the risk of adulteration,

– making foods more easily handled and stored by retailers and consumers,

– increased production output as a longer shelf-life enables a larger market to be found and year-round production possible.

Conclusion:

Consumers everywhere are increasingly looking at companies and brands to take the lead on environmental issues. And, as outlined above, the broad legislative trend toward bans and restrictions on unsustainable materials is encouraging the adoption of sustainable materials and practices.

For the food, beverage and restaurant industries, environmentally-friendly post-consumer recycled products can reduce environmental impact and contribute to the development of a truly sustainable economy, aligned trends.

Why choose PrimePac ?

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

5 Types Of Stand up Pouch Packaging And Their Advantage

What is stand-up pouches packaging ?

Stand up pouch packaging are the most popular packaging form used across various industries. This flexible packaging type offers multiple benefits to the companies and the users also. They are cost-effective compared to traditional rigid packaging.

Customers love them for the ease of storage and attractive designs. Companies love them for the ease of fill and distribution as well as the variety of options available.

Packaging makes the world go round! Well, the world of food and consumer products, anyway. Think that’s an exaggeration? Imagine today’s grocery/retail store aisle without effective product packaging, Exactly. Products not packaged appropriately are not likely to do well and customer satisfaction will be largely nonexistent.

Given the development of new packaging materials, manufacturers and distributors are presented with a seemingly endless variety of primary packaging choices: boxes, cartons, displays, bottles, composite cans, and flexible packaging to name a few. With all of these options, one stands out and is uniformly effective in protecting contents and convenient to the consumer, that is stand-up pouches!

Stand-up pouches in our life :

The stand-up pouches are being application in most of the industries. They are ideal for packaging food items. They are used for packaging across many industries like medical and pharmaceuticals, industrial items, gardening products, etc.

These pouches offer many benefits over the traditional packaging form. The current article details some of the most popular and widely used stand-up pouches in the flexible packaging industry.

Popular stand-up pouches types in life :

Flat Bottom Stand up Pouches

The flat bottom stand-up pouches are becoming increasingly used in the packaging industry. When filled, these pouches stand on their flat bottom on the shelves and attract the customer’s attention.

They also take less space on the shelves and thus more products can be displayed compared to other packaging types. One of the biggest advantages of using these bags is that they take lesser raw materials to manufacture (12% less film) and store more quantity.

Benefits:

For sure, it takes less energy to manufacture them and they weigh less as well, both of which reduce the manufacturing cost. The flat bottom stand-up pouches eliminate the need to use cartons for outer packaging of the product.

Benefits

It can be elegantly displayed on the shelves and are easily stackable which catches the customer’s attention. These bags come with a tearing zipper which makes it very convenient to open the bags.

Eco-Friendly

The flat bottom bag is also eco-friendly, as it uses less material to manufacture and stores a greater quantity of products. This reduces the carbon footprint of these bags.

Popular stand-up pouches types in life

Flat Bottom Bag with Tearing Zipper

The flat bottom bag with tearing zipper is ideal for packaging food products. It has a flat bottom and is stable.

Popular stand-up pouches types in life

Stand-up Bag

More brands are moving from the rigid packaging towards flexible packaging and stand-up bags are one of the most common flexible packaging options.

Benefits

These bags offer the most versatile and excellent printed graphics on the bag which will catch the attention of potential customers. They can be produced in a number of shapes and sizes which adds to their convenience.

The stand-up bags also provide an excellent moisture barrier and protection against other elements which keep the product safe for longer.

The stand-up packaging bags are inevitable when the objective is a cost reduction on the packaging. Rigid packaging costs at least 3-6 times more than the flexible packaging.

Benefits

The customers can open the packaging by sliding the zipper which is very convenient for them. the stand-up zipper bags are retail-ready.

The stand-up zipper bags are also an excellent packaging option for protecting the packaged products. They provide a high degree of protection from UV light, oxygen, moisture, etc.

thereby helping to keep the packaged products safe and fresh.

Cost-Effectiveness

They also ensure that no secondary outer packaging is required. This helps to save considerable costs on the packaging. These zipper bags also take the lesser volume in transportation and helps to save costs on transit and distribution.

Popular stand-up pouches types in life

Stand-up Zipper Bag

The stand-up zipper bags are one of the most prevalent forms of flexible packaging which comes with a zipper for easy opening and resealing of the package.

Popular stand-up pouches types in life

Spout Pouch

The spout pouches are convenient flexible packaging which is mostly used to package solid food products but they can be equally effective for storing liquid.

They are ideal for packaging small quantities of liquid food products like fruit juices, tomato ketchup, etc. They are manufactured using plastic which is chemically resistant.

Benefits

They are also mostly used in the personal hygiene industry for packaging products like shampoo, liquid soaps, etc. These spout bags are convenient to carry around while traveling.

Biodegradable Packaging and Stand Up Pouches

Biodegradable packaging. Most consumers have heard the term and many believe they know what it means. But do they? Despite increasing public concern about the environment, do people know which packaging materials are biodegradable? And is biodegradable packaging the only type that is environmentally friendly? Stand up pouches offer a good way to examine these issues.

Stand up pouches are generally not a form of biodegradable packaging. While many packaging materials made of polyethylene (PE) and polypropylene (PP) are biodegradable, they require a great deal of time and certain specific conditions in order to actually biodegrade in a landfill. Materials that do biodegrade are made of such things as paper, starch, wood pulp, potato, cotton, sugar beet, corn, to name but a few. However, although stand up pouches aren’t made of these materials, it doesn’t mean that they are bad for the environment.

Each stand up pouch is made via a very energy-efficient process whereby multiple layers of special film are laminated together to form a barrier bag that protects contents from vapor, odor, moisture, air, pests and/or light, depending on what the particular product needs. Of relevance to our discussion is the fact that although stand up pouches are made from multiple film layers, they actually take up to 12 percent less film to construct than most other packaging bags.

Less material ultimately generates less waste, of course, but there is another environmental benefit as well. Less material means less weight which means that less fuel per unit is consumed to transport stand up pouches.

Advantage of using stand up pouch

Strong Branding & Marketing

Rotogravure printing – the bright colours and graphic opportunities, strengthens brand presentation and recognition, ability to stand up on shelves, strong visual impression for sales

Advantage of using stand up pouch

Excellent Barrier Properties

Improve shelf life and protect the product from of moisture, oxygen, light, infestation, odour etc. or a combination of these

Advantage of using stand up pouch

Cost Reductions

Cost-effective light-weight packaging and transport, low material costs for pouches.

Advantage of using stand up pouch

Environment Friendly

Low packaging waste to dispose, recyclable, reusable and more environmentally-friendly

Advantage of using stand up pouch

Product Visibility

Visibility of products before purchasing through the use of transparent pouches or window pouches.

Advantage of using stand up pouch

Perfect for special applications and purposes

Customized pouches for special uses with microwavable, sterilizable, and pasteurizable material.

How stand-up pouches boost your business?

For Manufacturers

For the manufacturer, stand-up pouch packaging helps save on shipping costs as pouches are far lighter than bottles and jars. This allows for shipping of more product and less packaging, and are also space saving. Bottles, jars and cans take up a lot of room on trucks and in warehouses, but pouch material is supplied in roll form. Cost reduction is another benefit as stand-up pouches are less expensive than bottles, jars and cans.

For Retailers

The stand-up pouch also ends up benefiting the retailer once the product hits the shelf. With a flat front, the stand-up pouch is ideal for large graphics explaining what's inside (and the back provides plenty of room to meet labeling requirements.) It also allows for multiple display options as pouches can stand on flat shelves or can be hung from hooks at aisle-ends or on carousels. High shelf utilization is another benefit as less weight and more rectangular shape mean more product in a given length of shelving.

Flexible packaging – in every sense of the word

Boxes, cans and jars allow only so little packaging design options and stifle creativity. Stand up pouches, on the other hand, leave artists free to create virtually whichever packaging design they like. And that’s not all! Not only does flexible packaging allow the most interesting and gorgeous packaging designs, it also costs little to produce – no matter how colourful or ‘out of the box’ the design may be.

Stand up pouches are cheap to ship

When it comes to shipment costs, every gram and millimetre of packaging counts. Now, this is where stand up pouches really shine! For one, they are easy and cheap to have delivered to your site because they are so lightweight and hardly take up any space when flat. Once filled, stand up pouches still take up little space as they can be easily arranged in bunches to fit any box or stockroom. Secondly, a packaging designer who knows the tricks of the trade can easily tweak his design so that the pouches take up even less space!

Conclusion:

Stand-up pouches packaging not only meets the needs of consumers for product display, but also saves material resources and transportation costs for manufacturers and suppliers. The concept of catering to green consumption is an indispensable packaging option in the packaging market!

Therefor, is importan to choose a reliable stand-up pouches manufacturers. PrimePac, can help you !

How Primepac Can Help You in stand-up pouches Packaging?

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

Sustainable packaging research from design to shipping!

With the progress of industrial modernization, building materials, electronic waste, chemical waste, and white pollution that we often hang on our lips have become our environmental killers. Among these waste materials, except for a few copper, iron, metal, waste paper, etc., which can be recycled, the rest of the waste materials are disposed of by filling or incineration.

However, such a treatment method will cause a certain degree of damage to our environment. Environmental issues such as water pollution and air pollution are entangled around us.

In the face of scarce resources and increasing pollution, sustainable environmentally friendly materials have become the first choice of many businesses.

What is sustainable packaging?

Sustainable packaging is packaging that, over time, reduces its environmental footprint.

This can happen in a number of ways:

- Ingredients: Using raw 100% recycled or raw materials

- Production process: By minimizing the production process, supply chain, and carbon footprint

- Reusability: Creating a circular economy around the packaging, extending its lifecycle and usability.

As consumers become more aware of their impact on the environment’s safety and future, they are taking bigger steps to live more sustainably, whether through making their homes more energy-efficient or buying products that are packaged with recyclable, sustainable materials.

Thus, sustainable packaging is showing up everywhere in our life – potato chip bags, beverage bottles, CD cases, cosmetics, and more.

Are you really know sustainable packaging?Follow this article, we’ll tell you everything about sustainable packaging you may want to know!

sustainable packaging material:

There are many sustainable packaging on the market, but most of them are used the similar material, and the most common sustainable packaging in our life are as below :

sustainable packaging material

Kraft packaging

Kraft paper bag structure: Kraft paper bag is a composite material or pure kraft paper packaging container, non-toxic, odorless, pollution-free, low-carbon environmental protection, meets national environmental protection standards, has high strength, high environmental protection, is currently the most popular in the world One of the environmentally friendly packaging materials.

sustainable packaging material

Paper packaging

When it comes to paper packaging there is a lot to take in, like did you know that there are in fact 4 different types of paper packaging,

- Kraft

- White cardboard

- Coated paper

- Offset paper

Paper Packaging is a versatile and cost-efficient method to transport, protect and preserve a wide array of items. It is engineered to be sturdy, yet lightweight, and is customizable to meet product- or customer-specific needs.

sustainable packaging material

Pp woven bags

PP woven bags are made from polypropylene resin. Polypropylene, which is also known as PP for a short name, is one kind of thermoplastic resin material. During our production process, it is first made into a plastic film, then drawn into flat tapes. And then the polypropylene tape will be woven in two directions (warp and weft) to create a light, but strong and heavy-duty fabric, which will be used as the main material for packaging making, hence the name woven package.

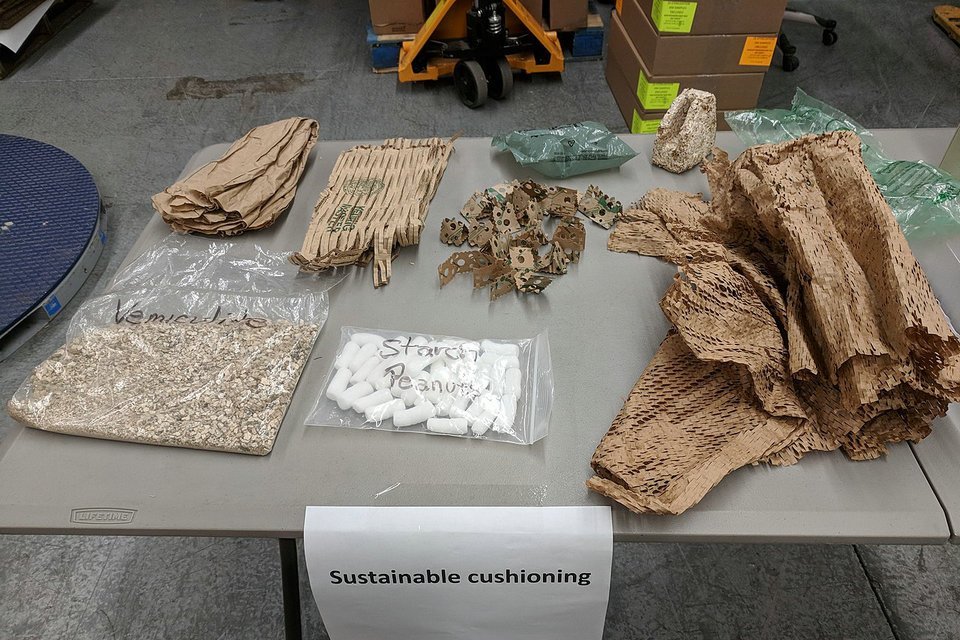

Tips for sustainable packaging and shipping:

However, sustainable packaging are commonly used in our daily life. As consumers become more conscious of their shopping habits, they’re looking not only for sustainable products but businesses dedicated to being environmentally friendly in all aspects of their operations.

Here are some of their tips for sustainable packaging and shipping:

- Offer carbon-neutral shipping by offsetting emissions

- Ship items in bulk

- Use sustainable packaging that can be repurposed

- Offer a returns program for your empty product containers

- Recycle on behalf of your suppliers and offer shipping-friendly items

- Work with wholesalers to reduce individual shipments and limit return shipping

- Reduce the size of your packaging

- Use compostable mailers

After we have talked so much about sustainable packaging, you must be interested in sustainable packaging. And the most interesting aspect of the packaging is not only the sustainable materials, but also the sustainable packaging design concept!

Do you know what sustainable packaging design is? Let’s have a look!

sustainable packaging design:

The sustainable design of products requires designers to not only meet the needs of users when designing products but also pay attention to energy consumption and environmental pollution in the production and use of products. For different design objects, designers can make the design consistent with the concept of sustainable development from a single or multiple perspectives.

Therefore,meet the sustainable design,we have 5 points needs to consider :

1. Design concept

The creative and design stages are the key to achieving sustainable products. Designers can improve existing products or design products that are more conducive to sustainable development based on the existing use problems. Many products are now pursuing multi-functionality to attract daylighters, but there are not many functions actually used, which results in excess product functions and is a waste of a certain degree. In this regard, designers can re-examine the functions of existing products and optimize the functionality of products. In addition, extending the product life cycle also requires attention when designing the concept. The frequent replacement of products in a short period of time is a great waste of natural and social resources and is naturally unsustainable.

2. Green materials

The greening of materials not only refers to the green choice of materials, that is, the selection of environmentally friendly and legally harvested natural materials in the design, but also can reduce the use of materials or avoid the use of materials without affecting the basic function and strength. Low utilization, reducing waste of materials.

3. Recyclingmaterial

In a circular economy, all products should be designed to be biodegradable, recyclable, or a combination of both. Through recycling, all materials and components in the product can be recycled for new products or new processes, thereby avoiding any waste. Therefore, in the early stage of product design, designers should fully consider the possibility of recycling their parts and components, and achieve the purpose of recycling through existing technology treatment methods and processes.

4. Energy saving

Energy saving is mainly reflected in the three parts of manufacturing, transportation and use in product design. When designing products, designers need to consider the production consumption in the manufacturing process, reduce energy consumption, reduce production processes, and improve energy efficiency. In transportation, designers can also use stacking, folding, and disassembly to reduce transportation costs. In the process of user use, it is also the most energy-saving part of the entire design. Designers should reduce energy consumption in use through design concepts.

5. Reduce environmental pollution

The initial design models of products are often rough. In order to pursue refinement and beauty, designers usually treat the surface of materials to different degrees, the most common of which are sanding and painting. However, the use of paint can cause pollution to water, air and even soil. So sustainable design requires designers to consider more environmentally friendly processes.

Your consumers are increasingly concerned with the impact they’re making on the environment. This inclination is even more common with the millennial generation, where the majority of these consumers not only recognize but want to fix the impact of years of unsustainable practices.

Today, product manufacturers like you have to walk a fine line between package sustainability and quality. You need sustainable packaging that provides a safe barrier from elements like moisture and cold air. You also have to ensure that your packaging is shelf-stable and that it doesn’t feel flimsy or cheap.

Cost-Effective Packaging Solutions

While many people may think that environmentally-friendly products are unavoidably expensive, such as organic foods that can often be double the price of others, sustainable packaging is actually cost-effective. Innovative designs that use less harmful materials not only reduce waste, but they also reduce space. The ability to fit more weight and more products within shipments can greatly lower shipping and transportation costs, allowing for more products per shipment and reducing the use and cost of fuel.

Promote the Product

Let’s face it: Consumers feel better and happier when they know they are contributing to a greener future. Keep your customers satisfied, and associate your product and your brand with greener living. When you show customers that you care about the environment and how your product affects the safety of others, you’ll gain a positive reputation that help promote your business and product.

A Greener Future

Plastic materials such as PVC (polyvinyl chloride) are not biodegradable, and some chemicals used in PVC production have been shown to cause cancer, kidney or reproductive system damage in animals. The H-Loc Trapped Blister uses recycled PET (RPET) to contain products, and a minimal amount at that. The majority of the package uses corrugated cardboard, the most recycled material on the planet. And with water- and soy-based inks and adhesives, the trapped blister reduces the need for harmful oils.

Save Yourself Money Sustainable Packaging

Sustainable and eco-friendly products tend to be packaged in more lightweight materials which ultimately can help you save on shipping costs. Think locally when sourcing freight carriers and materials for packaging. A well-thought-out logistics plan will directly impact your costs in a positive way. Not to mention your consumers will also appreciate it when products are lightweight and easier to recycle.

How Do Brands Benefit from Sustainable Packaging?

There are many ways a brand or manufacturer can benefit from a focus on sustainability in its production. One huge advantage to eco-conscious packaging is that it will attract a demographic of environmentally conscious, like-minded consumers to your product. This demographic is growing fast and if you aren’t supporting the eco-friendly movement with your brand now, you are going to be left behind your competitors in the marketplace.

This is a call to arms for your product lines! The customer base for eco-friendly companies is steadily growing, as people are becoming more aware of the damaging effects that modern living—packaging included—has on the environment.

Prominent companies such as Walmart and Coca-Cola have already invested in sustainability-related packaging, in part because it is a lucrative transition to make. The Coca-Cola Company made its product packaging more sustainable by adopting more resource-efficient designs, as well as using recycled and renewable materials. Since investing in sustainability, Coca-Cola reports it has saved approximately $180 million a year.

Conclusion:

As consumers become more aware of their impact on the environment’s safety and future, they are taking bigger steps to live more sustainably, whether through making their homes more energy-efficient or buying products that are packaged with recyclable, sustainable materials.

At the same time, sustainable packaging also has a lot of positive impacts on companies, bringing more environmental protection concepts to consumers and improving brand image. Green and healthy brands are first for many consumers!

PrimePac adheres to the green business philosophy of sustainable and environmental protection, with sustainable packaging as its main business product, and is the perfect candidate for your packaging business partner.

About primepac:

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

PP Woven Bags - The Useful Guide

What are pp woven bags? Here is the complete guide to pp woven bags you need to know!

Pp Woven bags are quite popular products on the market with many different uses. Follow this article, let’s learn more about this new type of environmentally friendly packaging. All you want to know about pp woven bags is here!

What is pp woven bag?

PP woven bag is made from polypropylene resin. Polypropylene, which is also known as PP for a short name, is one kind of thermoplastic resin material. During our production process, it is first made into a plastic film, then drawn into flat tapes. And then the polypropylene tape will be woven in two directions (warp and weft) to create a light, but strong and heavy-duty fabric, which will be used as the main material for packaging making, hence the name woven package.

1. Woven

Woven, or weaving is a method by many threads or tapes woven in two directions (warp and weft), to form a fabric for plastic industry needs.

In the plastic woven industry, with a plastic film is drawn into filaments, woven into fabric/sheet/cloth. It can be into a tarpaulin, woven bags, container bags, tons of bags, geotextile fabric, color of the cloth and so on.

2. Woven polypropylene

Polypropylene, which is also known as PP for short name, is one kind of thermoplastic resin material that produced by the polymerization of propylene. Thus, woven polypropylene is polypropylene strips/threads that have been woven in two directions (warp and weft) to creat a light, but strong and heavy duty material.

Different names of pp woven bags

different regions have different names for different products. Here are the different names for pp woven bag

1. Pp woven bag = woven polypropylene bags = woven polypropylene sacks

2. Short names of woven polypropylene bags

pp bags

wpp bags

woven bags

woven pp bags

woven poly bags

What’s the types of pp woven bags?

There are different types of packaging according to different materials. Therefore, there are also different types of pp woven bags.

Different types of pp woven bags

Traditional PP woven bags

Products made of woven uncoated or woven PP bonded, white or colored plastic. Products folded bottom garment, open mouth. On printed or non-printed Flexo 2-sided cover, simple images or colors or according to customer requirements. The bag withstands a load of 5 –50 kg. Products used to pack animal feed, seafood, agricultural products, fertilizers, flour, salt, sugar, chemicals, raw materials ...

Different types of pp woven bags

PP Woven Bag Laminated Film

Products made from woven PP laminated BOPP film, translucent or BOPP gravure seal. How bottom folds sewing, open mouth. The ends are folded with a splint, sewed with cotton thread or stuck with a PP flap (bag with a block shape), with a corner shaped valve. 2-sided printing covers, multicolored, beautiful, sharp images, images and colors according to customer requirements.

Different types of pp woven bags

PP Woven Bag and Bottom Splint

The bag has 1 layer of PP woven fabric coated with PP bonding plastic. The ends of the bags are glued or not glued with PP strips, folded with a brace and sewed with cotton thread, shaped at the corner, the valve has a 1-way principle, self-closing. 2-sided Flexo printing covers, images, and colors according to customer requirements.

Different types of pp woven bags

PP Woven Bag with Bottoms

The bag has 1 layer of PP woven fabric coated with PP bonding plastic. The two ends of the bag are covered by rectangular PP adhesive when the material is closed, it will be in the form of a block, with an inlet valve at the corner, the valve has a 1-way principle, self-closing.

What’s the production process of pp woven bags?

Tape Extrusion

Tape extrusion is the most critical process of the woven industry since the quality of the tape has a direct impact on the quality of the packaging. During the extrusion stage the mixture will be heated to a specific temperature for plasticization, and then extruded in a flat sheet and cooled in a water tank. After the initial cooling, the flat sheet will then be split into strips by high-precision cutters. After the splitting, the flat tape will then be heated, stretched, and cool multiple times to achieve the required linear tensile strength.

Circular weaving

Woven packaging is made from tubular fabric which is weaved by a circular weaving machine using PP flat tape. Shuttles in the circular weaving machine weave the tape in the weft and warp direction to form the woven fabric in a tubular structure.

Rotogravure printing

To achieve the aesthetic and advertisement property of our packaging, the woven package will be laminated with a layer of BOPP film above the woven fabric. The Biaxially Oriented Polypropylene (BOPP) film is printed using a rotogravure printing machine. And based on customer requirements, another background layer of pearl white or aluminized film can be added between BOPP film and the woven fabric.

Bag Making

Bag making mainly consists of 3 major processes: lamination, side gusset, and bag making. Lamination is one of the most critical processes for woven packaging making. BOPP film and woven fabric are laminated using a mixture of PP and LDPE. It’s melted and then laminated between two layers to form a bond. Temperature control and cooling is the key control point for a desirable bonding.

However, there are the reasons why more and more business chooses pp woven bag. The Australian government introduced a new environmental protection policy in 2018, and officially began to stipulate that all enterprises should focus on energy conservation and environmental protection. We strongly advocate the Increase use of recycled material and build demand and markets for recycled products. From July 1st, all major shopping malls and supermarkets in Australia are restricted to provide plastic bags. From then on, all businesses have begun to find solutions for environmentally friendly packaging.

Therefore, in this article,you’ll find the answer what’s the benefit of using pp woven bag and what’s the properties of pp woven bags!

Properties of pp woven bags and what’s the benifit ?

Pp woven bags are 100% reusable and durable

Pp woven bags are Light in weight and flexible

With excellent resistance to stress and high resistance to cracking

Pp woven bags can breathable or waterproof with a laminated film

Pp woven bags allow the contents to breath until air dried.

Pp woven bags have better burst strength than plastic bags.

Pp woven bags can be laminated as the vapor and moisture barrier.

Pp woven bags can be partially transparent for outstanding presentation.

Pp woven bags can be side gusseted to accommodate bulky items easily

So you may wondering is woven polypropylene an eco-friendly material?

- Yes, it’s an eco-friendly fabric. It can be melted down, recycled and made into other products. Besides, they last long enough and can be used many times to reduce your demand from single-use products.

When it comes to creating your very own custom reusable bags, you want something durable and eco-friendly, but when faced with your options it can be hard to make a decision. If you’ve narrowed down your options to recycled plastic, that’s a start, but you still need to make the call between woven vs. non-woven polypropylene bags.

So What’s the different between PP woven bags and Non pp woven bags?

Woven Polypropylene

Woven polypropylene is made when recycled plastic is stretched into long threads. These threads are then woven in a way similar to how cotton and other fabrics are woven. This woven construction lends the fabric lots of durability.

Non-Woven Polypropylene

Non-woven polypropylene is also made using recycled plastic stretched into threads, but those threads are bonded together. The resulting fabric is also very durable, it also has a smoother surface.

Both woven and non woven polypropylene bags are made from recycled plastic. The difference is in how they are built. To make woven polypropylene plastic threads are woven together in a more traditional manufacturing process to create a durable material. To create non woven polypropylene plastic fibers are bonded together. In both instances the fabric is durable, and when used to make reusable bags they will deliver years of dependable use.

Application of pp woven bags

- Agricultural product packaging: PP woven bags are largely used in storing and transporting agricultural products such as aquatic products, feeds, fruits, vegetables, etc. PP woven bags used in the agricultural industry typically include feed PP woven bags, chemical PP woven bags, fertilizer PP woven bags, vegetable weaved bags, and fruit mesh bags.

- Food packaging: PP woven bags are increasingly used to pack food. Common food woven bags include rice PP weaved bags, flour PP woven bags, maize woven bags, etc.

- Geotechnical engineering: PP woven fabrics are extensively used in the construction of irrigation works, roads, railways, ports, mines, buildings, and more. Having the functions of filtering, draining, isolation, and anti-seepage, PP woven fabrics are one of the most popular geosynthetics.

- Tourism and transport: Temporary tents, sunshades, and various travel bags can be made with PP woven fabrics. In addition, plastic woven fabrics can also be used as fences and screens during construction.

- Daily necessities: PP woven bags are almost used by everyone, whether workers, farmers or cargo agents, etc. You can find plastic woven products (such as shopping bags, logistics bags, etc.) in stores, warehouses, and houses, nearly everywhere.

- Flood control products: Woven bags play an important role in reducing or preventing the detrimental effects of floodwaters. They are widely used in the construction of dams, river banks, roads, and railways. Woven polypropylene sandbags are widely used all over the world.

- The special woven bags: The special woven bags also are used to serve some special purposes. For example, UV-resistant woven bags have UV protection and anti-aging function, allowing them a longer lifespan in the sunlight. A woven polypropylene tube with UV protection can be used for earthbag buildings.

Conclusion:

With the gradual strengthening of people’s awareness of environmental protection, environmentally friendly products have become a new challenge faced by various enterprises. For packaging products of the same weight, PP woven bags can be lighter than ordinary plastic packaging, use less plastic, and meet the environmental protection trend of lightweight packaging. Thus, pp woven bags are definitely your best partner for environmental protection.

At the same time, choosing reliable pp woven bags manufacturers in China is also important!

Primepac - Your best pp woven bags manufacturers & supplier

Pp woven bags from PrimePac:

Why choose us ?

1.All food-grade raw materials are used, no recycled materials are used, and no odor. At the same time, the strength is more reliable. The raw material supplier is Sinopec (the world's total market capitalization in 2019, the first in the petrochemical industry)

2.Our PP woven bags are produced in BRC certified food grade plants

3.Higher printing quality with our PP woven bag

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

Kraft paper packaging - A comprehensive overview

Everything you need to know about Kraft paper packaging

With the ever-growing awareness of environmental issues among the population, consumers are increasingly turning their loyalties to eco-conscious businesses and products, with one of those products being kraft paper packaging. With more and more plastic restrictions being put in place around Australia, from straws to plastic bags, these eco-friendly measures have had strong support from people!

One of the trends growing is the use of Kraft paper packaging as a more and more popular packaging method, what effect does it have on the environment? What made it a popular packaging method for both businesses & consumers? In this article, we are going to learn more about Kraft paper packaging and sustainable bags.

What is kraft paper packaging?

Kraft paper bag structure: Kraft paper bag is a composite material or pure kraft paper packaging container, non-toxic, odorless, pollution-free, low-carbon environmental protection, meets national environmental protection standards, has high strength, high environmental protection, is currently the most popular in the world one of the environmentally friendly packaging materials.

Kraft paper bag is based on the whole wood pulp paper. The color of the kraft paper packaging is divided into white kraft paper and yellow kraft paper. PP film can be applied on paper to play a waterproof role. The strength of the bag can be made from one to six layers according to customer requirements. , Printing and bag-making integration. Opening and back cover methods are divided into heat seal, paper seal, and paste bottom. Scope of application is generally: chemical raw materials, food, pharmaceutical additives, building materials, supermarket shopping, clothing, and other industries suitable for kraft paper packaging industry.

Where did the word ‘Kraft” come from?

Kraft paper is a packaging material that gets its name from the Kraft pulping process, pioneered by Carl F. Dahl of Germany in the 1880s.

Normally, in the manufacture of paper, wood is ‘pulped’ (ground to a pulp) first, but Dahl found that treating the cellulose pulp with certain chemicals (sulfates) increased the strength of the paper. He called his paper Kraft paper – Kraft in German means ‘strength’.

This is why this type of material was eventually used as a packaging material due to its durable and useful nature in kraft paper packaging.

When it comes to kraft paper packaging, you must have heard of sustainable packaging!

Kraft packaging is one of sustainable packaging, so what other styles are there in sustainable packaging? First, let’s see what is sustainable packaging

What is sustainable packaging?

Sustainable packaging is the development and use of packaging that can improve sustainability. This involves increasing the use of life cycle inventory (LCI) and life cycle assessment (LCA) to help guide the use of packaging, thereby reducing environmental impact and ecological footprint. It includes the entire supply chain: from basic functions to marketing, to retirement (LCA) and rebirth. In addition, the ecological cost-to-value ratio may be a useful goal to improve the long-term viability and quality of life of humans and the longevity of natural ecosystems. Sustainable packaging must meet current functional and economic needs without affecting the ability of future generations to meet their needs. Sustainability is not necessarily the end state, but a continuous improvement process.

We all know that sustainable packaging is a relatively new addition to packaging environmental considerations. It requires more analysis and documentation to look at packaging design, material selection, processing, and life cycle. This is not just a vague “green movement” that many businesses and companies have been trying to include over the past few years. Companies implementing these environmental initiatives are reducing their carbon footprint, using more recycled materials, and reusing more packaging components. They often encourage suppliers, contract packers, and distributors to do the same.

Different elements of sustainable packaging to consider

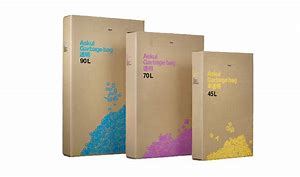

What are the types of sustainable packaging? In addition to the kraft paper, you must have seen the following types.

Sustainable packaging

Kraft

Kraft paper is 100% sustainable, and among one of the most popular packaging materials in the world. It is much more sustainable to manufacture kraft paper compared to regular paper. Kraft is produced from all-natural ingredients such as pulp from all types of wood, while regular paper uses specific woods.

Bleaching is also not involved, which maintains the strength of the paper and decreases manufacturing costs. Kraft paper is also a lightweight packaging material that helps maintain a low shipping cost.

Molded pulp

This material is no stranger to sustainable packaging. A growing sustainability trend of large and small brands alike are opting to use molded pulp more often than other packaging options. Created with paper fibers, either virgin or recycled, molded pulp is one of the most sustainable packaging options on the market right now.

It is very common to find electronics and home appliance companies that use molded pulp inserts. The protective and thermoforming capabilities of this material allow for more packaging options. This is perfect for products that come in any shape or size.

Sustainable packaging

Foams packaging

A very large part of the packaging industry is the use of foams. Packaging foams are materials used in different levels of the industry. It is used as a duo-purpose protective layer, as well as to organize small products to provide a good presentation. But, foams were not always the most environmentally friendly.

As the subject of sustainable packaging continues to rise, biodegradable and paper foam alternatives have been developed to replace this material. Since the market for sustainability is growing, it is beneficial for smaller companies to ride the momentum.

Sustainable packaging

Inks in packaging

The use of sustainable inks is a rising trend. These links no longer need heavy metals like lead and mercury. The biggest difference is the reduction or complete removal of volatile organic compounds. These compounds produce gases that are hazardous to both the environment, and human health.

Although energy-saving initiatives are in place, biodegradable inks have been the most impactful. These inks use organic vegetable oils. The result is a reduced impact on the environment and allows lower energy consumption during the recycling process in kraft paper packaging.

How many types of kraft paper are there?

1: According to the material can be divided into:

- Pure kraft paper bags;

- Paper-aluminum composite kraft paper bag

- woven bag composite kraft paper bag

2: According to the bag type, it can be divided into:

- Three sides sealed kraft paper bag;

- Side organ kraft paper bag;

- Free standing kraft paper bag;

- Kraft paper bag with zipper;

- Freestanding zip kraft paper bag.

3: According to the appearance of the bag type, it can be divided into:

- square bottom bag;

- seam bottom bag;

- valve pocket;

6 types of kraft paper and their best business uses

Virgin Natural Kraft Paper

Virgin natural kraft paper is the heavy lifter of the paper world. Its clean and durable fiber content and its low cost make it an ideal option for heavy-duty applications that require a high level of tear resistance. Plus, it’s perfect for printing as well, so it’s a natural for branded packaging and protective layering, wrapping, pallet interleaving, carrier sheets, and dunnage.

Natural Recycled Kraft Paper

Although not as strong and tear-resistant as virgin natural kraft, natural recycled kraft paper is a more environmentally friendly option, and still carries enough strength to do an excellent job with dunnage and void fill applications, as liners for trays and boxes, interleavers, and bottom wrap for newspapers. Both virgin and recycled kraft paper come standard in weights from 30# to 70#.

Black Kraft Paper

The most common use of black kraft paper is as a dark, durable backing for picture frames, but that’s not its only use. Black kraft paper is also perfect for fun and interesting craft projects, or as an aid to unique decorating where light barriers and dark borders are needed.

Colored Kraft Paper

Colored kraft paper is available in just about every color of the rainbow. Its vibrant hues make it perfect for all manner of craft projects, as well as fun backings for bulletin boards, standard school supplies, scrapbooking, and similar applications. If your target market includes, schools, daycares, or busy parents, colored kraft paper should be on your list.

White or Bleached Kraft Paper

Similar to virgin natural kraft in strength and durability, white or bleached kraft paper makes an especially powerful impact when a crisp, clean appearance is desired. For example, many restaurants like to use white kraft paper as an attractive and economical alternative to linen tablecloths. It also serves well for wrapping and can stand up well to the standard wear and tear a package may receive.

Printed Kraft Paper

Many different industries take advantage of the versatility and value of custom printed kraft paper for creating branded wrapping, packaging, and in-store displays. For example, a deli may order a supply of kraft paper sheets in the perfect size for wrapping sandwiches and have the deli logo and contact information printed on one side as a means of affordable, continual advertising. Many fashion manufacturers ship their garments out with printed kraft paper sleeves or sheets between individual articles, or wrapping the inside of a shoebox, again with branded logos and other information prominently displayed in kraft paper packaging.

Why we choose kraft paper for packaging

Cost

The cost of packaging adds to the final cost of any product, which ultimately affects how your product will compete with the rest of the market. Kraft paper packaging is less expensive than plastic packaging. It also weighs less than packaging products that include features like zip closures. The weight of the packaging determines the cost of shipping, which also affects the final consumer price in kraft paper packaging.

Strength

Kraft paper is durable enough to withstand elaborate printing in modern, high-tech machinery. This means you have endless options when it comes to designing your packaging’s printing. It also holds up to shipping and shelf life very well.

Environmental Impact

Both paper and plastic are easily recyclable, but paper has an environmental edge because it also quickly decomposes if it’s thrown away instead of recycled. Therefore, you don’t have to depend on the consumer to make a good environmental choice; kraft paper is environmentally low-impact whether it’s recycled or sent to a landfill.

First and foremost, kraft paper packaging is stronger, due to its reduced lignin content and high sulfur ratio. It also doesn’t involve extensive bleaching, which decreases the paper’s strength and increases manufacturing costs.

Since it doesn’t add much weight to the package, using kraft wrapping paper keeps shipping costs down. • Its coarse texture, durability, and flexibility provide more protection.

For Your brand image

Use Kraft paper for eco-friendly business cards. • The natural quality gives business cards a look that is simple and universally appealing. • Potential clients will appreciate your environmentally conscious stance and view it as a credit to your character. • Your cards will garner attention due to their unique look.

Conclusion

After we know so much about kraft paper packaging, let's summarize the advantages of kraft paper!

Recyclable

Most of the paper packaging that is available in the stores is recyclable.

Recycling paper packaging is more comfortable than plastic packaging.

Even some types of paper are used for the packaging can get into their original form after recycling it again and again.

Good Printing Performance

The kraft paper packaging is considered best to give an excellent printing performance.

As compared to plastic packaging the kraft paper packaging can provide impressive printing results.

Durable material & Saves space

Kraft paper packaging with a window relative to the width of the wear rate is relatively low, can be stored for a long time, after a long time will not decay, easy to save. Kraft paper boxes can be folded at Will and can occupy fewer places.

Why choose Primepac

PrimePac – based on Australian which was specializes in packaging production and design. In the area of kraft packaging industry, there are more unique technological advantages:

1 . Compared with custom pouch products, PrimePac can provide stock pouch products

2 . Print this directly on kraft paper. Compared to many kraft papers, only simple text and artwork can be printed. Primepac can print high-resolution CMYK patterns.

3 . Compared with many brown kraft paper / white kraft paper, PrimePac has more choices. We have made five kinds of paper materials, brown kraft paper / white kraft paper / cotton paper / yunlong paper / coated paper, which will also meet customer needs in the future and make more Many other attempts.

4 . Degradable technology, because the degradable film can not reach the performance of commonly used plastic film, primepac’s degradable packaging materials are basically in the form of kraft paper composite degradable film.

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

All About Paper Packaging You May Wonder

All you need to know about paper packaging!

When it comes to paper packaging there is a lot to take in, like did you know that there are in fact 4 different types of paper packaging? Not all packaging is suitable for food and Australia and New Zealand have new guidelines and laws which will affect your business! By reading this article you will have a better understanding of what you need to do for your business paper packaging needs.

The first on our list is Kraft packaging, Kraft packaging is a type of paper packaging specially designed in the 1880s by Carl, F. Dahl in Germany. He found by treating the paper pulp packaging with certain chemicals he was able to create a stronger, more resilient type of package.

Why the word Kraft?

So why the word Kraft in Kraft packaging? Well in German it means “strength”.

What is kraft packaging made of?

Like normal paper, the packaging is made of wood pulp, with an extra ingredient, sulfate, which increases the strength of the paper. In general, there are two major types of Kraft packaging. Type one: Coated unbleached Kraft (CUK), and type two coated recycled Board (CRB).

CUK paper packaging

CUK is the most standard and basic version of the Kraft paper packaging with it following the basic patent principles of Kraft paper. This version has benefits of being thin, tear resistant, and a high degree of stiffness.

CRB packaging

This Kraft packaging is made from recycled paper, which tends to make it a cheaper alternative to CUK paper packaging. However, it does have its downsides due to having less strength/tear resistance vs CUK however where strength/tear resistance problems are non-existent/low cause of concern CRB is a great way to save costs for your business!

Is Kraft packaging eco-friendly?

Kraft packaging is 100% eco-friendly. Left to nature it will naturally degrade within a few weeks leaving no trace behind. Or better yet it can be sent to be recycled to be used again. To sum up Kraft packaging is a strong, eco-friendly package.

Main uses for Kraft packaging

You all see Kraft packaging designs on a daily basis. They are perfect for groceries, fast food restaurants, clothes bags, gift wrapping, hey you can even make your business cards out of them to give that extra strong message about your business commitment to the environment! Kraft paper can be used for a multitude of different areas.

What is white cardboard?

White cardboard or paperboard is another popular choice of paper packaging. The major difference between cardboard and paper is obviously the thickness. Cardboard in general terms is thicker than 0.3mm and a grammage of 250g/m2. It was invented in England in the 1860s as a way of storing products. Like Kraft paper it is easy to ship. Cardboard also has the advantage of being able to be flat-packed and set up on site.

What is it used for?

White cardboard is used on a daily basis from everything to TV boxes, to storage to milk cartons. The use of cardboard is only limited to your imagination.

Is white cardboard environmentally friendly?

Cardboard like Kraft packaging is generally 100% biodegradable. There are however instances of cardboard not being completely environmentally friendly. The first instance is when a plastic or wax seal is layered on top which makes it harder to recycle. Another is like Kraft paper it becomes more environmentally friendly when the material is redistributed to the market via recycling.

What is coated paper?

Coated paper is paper which has a layer on top to stop liquids soaking in such as ink. This design choice can completely change the overall feel of the product.

Coated paper vs uncoated paper

Coated paper is what gives you that shiny, matte, glossy or semi-glossy feel to your design while uncoated paper is paper which allows liquids to soak in easier. You can think of it like the inside of a book is uncoated paper. while your milk carton is coated paper.

Is coated paper packaging recyclable?