Wonderful Eco-friendly packaging ideas

Introduction

Before we go deep into the topic of eco-friendly packaging ideas, let's talk about the word "eco-friendly" itself.

It can be one of the words you hear the most in all these years. The food, the cars, the advertisements, the product labels, and the instruction of your phones, the list can go on and on. And I am sure you will find more footprint of the word "eco-friendly".

"Eco-friendly" gained popularity for people's rising awareness of environmental protection.

After serious damages to the environment in particular. It sounds like a result of a sad story. Despite that, the good thing is being eco-friendly has been the trend.

However, do you know really know what eco-friendly is?

Here's the definition on Wikipedia below,

"Environment-friendly processes, or environmental-friendly processes (also referred to as eco-friendly, nature-friendly, and green), are sustainability and marketing terms referring to goods and services, laws, guidelines and policies that claim reduced, minimal, or no harm upon ecosystems or the environment."(source: https://en.wikipedia.org/wiki/Environmentally_friendly)

As you can see, this is a huge topic that can cover every detail in life. But The meaning of eco-friendly varies from one to another.

For packaging accordingly, it refers to packaging products with less or no harm to the environment.

The topic was not strange to you.

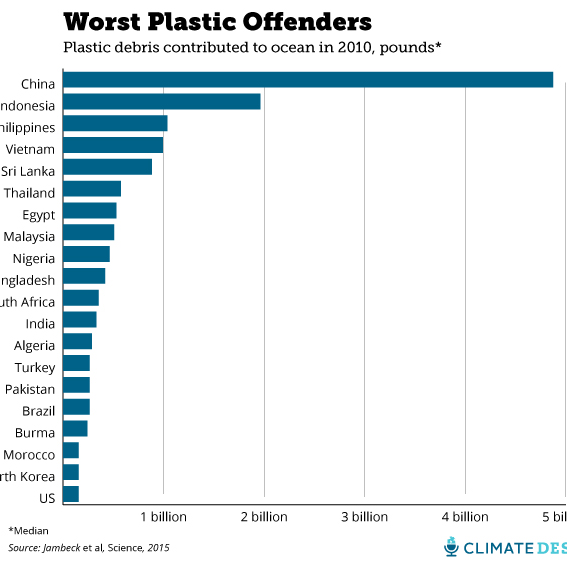

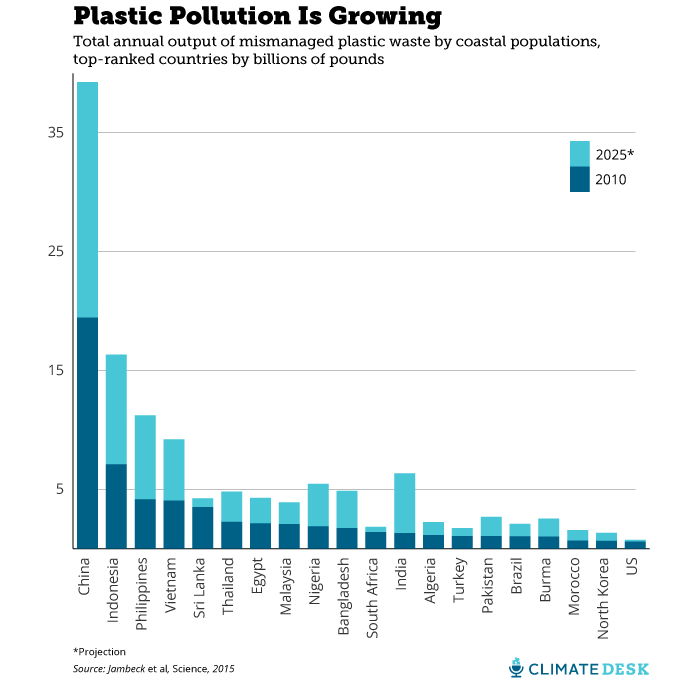

Plastic was once the tumor of the packaging industry for environmental issues. The abuse of single-use and non-recyclable materials has caused many problems. Landfill, harm to animals, marine pollution, and more. The list is long.

Therefore, eco-friendly packaging solutions have become more crucial than ever.

Packaging has played a big part in life after all.

Eco-friendly packaging ideas #1: More than environmental protection

The importance of eco-friendly packaging is more than the reduction of environmental impact.

About society and economy

Eco-friendly packaging is also a topic about society and the economy. Isn't it way too much?

No kidding, if you take a look at the big picture.

As we all know, the environment and culture are the roots of society. The sun, the air, the water, the plants, the animals, and other things altogether. Any single part gets problems, the trouble occurs to the others. Global warming, the coronavirus, and plastics pollution, and any other issues you could name and remember.

Several countries and going to disappear, if the high temperature continues. And most of the entire world has hardly moved forward under the epidemic situation. The global economy has plunged.

All these matters result in threats to humanity's survival. No need to mention the impact on the economy and society. The logic is easy. No environment, no survival, and no business in the end. And it is the result of the overuse of the environment or harmful actions to it.

The business model benefits all involved. Packaged goods companies reduce material costs, gain positive community attention, rebrand themselves as environmentally conscious, and gain actionable data on an emerging subset of their target population.

End-users gain the satisfaction of knowing they are minimizing their carbon footprint and introducing their loved ones to best practices.

So, being eco-friendly helps with not only environmental protection but the development of society.

Business benefits

As one of the key elements in society, business shares the benefits of eco-friendly packaging. By adopting eco-friendly packaging ideas, your business will enjoy benefits like

1. Increased brand vision & identity. Because consumers tend to choose companies and products caring more about the community.

2. Enhanced customer satisfaction with eco-friendly packaging solutions easier to dispose of or recycle.

3. Potential sales growth resulting from increased brand vision, identity and customer satisfaction.

4. The reduced carbon footprint of your business by eco-friendly packaging solutions.

5. Lower costs to deal with environmental problems by the production in the long run.

Now that eco-friendly packaging is so important, what can we do to support it?

A simple and easy way. Use eco-friendly products and solutions.

However, we probably need to know it first. What options do we have as eco-friendly packaging solutions?

Eco-friendly packaging ideas #2: Types of eco-friendly packaging

Generally, there are 2 types of eco-friendly packaging by the ways to use. They are (a) recyclable packaging and (b) reusable packaging.

Recyclable Packaging

Recyclable packaging refers to packaging easy to recycle after disposal. Typically, the materials to produce recyclable packaging are compostable and biodegradable. For example, paper-based packaging. Also, recyclable packaging usually comes with the feature of easy transit.

Common Recyclable Packaging Products

Paper-based packaging

Paper-based packaging is biodegradable, hence unlikely to take much space of the land. And the recycling of paper-based packaging is easy even if it ends up in the landfill. Because the raw materials are well processed before mass production.

After the main paper material finishes their missions in the frontline, the leftover pieces continue the cycle. Scrap paper is the raw material of a variety of products such as fiber-board, paper sacks, wrapping paper, and more.

Moreover, many companies are adopting and developing paper-based bottles as containers for coffee, soft drinks, and other beverages. You can easily find the paper coffee cups when you try to get some coffee in many coffee shops today.

At the same time, the usage of paper bags to keep dry foods has become prevalent such as coffee, tea leaves, snack food and nuts, cookies and candy, and spices.

Because paper-based materials can keep the freshness of the food by "keeping their breath".

All in all, paper packaging is a wised choice with eco-friendly packaging ideas. It is a competitive alternative over the other packaging solutions. (source: https://www.primepac.com.au/food-packaging-market/)

Also read Food Packaging Market Insight to know more about the food packaging market.

Although paper-based packaging solutions are popular for food packaging today, corrugated cardboard might not good at preserving food. And the other fragile products either. Because the cardboard alone might not offer enough strength. And exposure to moisture and humidity can kill the cardboard.

However, thanks to evolving technology, there are still many paper-based options other than corrugated cardboard. Check the paper-based packaging solutions now.

Bio-based Plastics

If the plastics are more attractive to you. The bio-based family in the tribe of plastics is the one with eco-friendly packaging ideas.

Bio-based plastics get their names because they are biodegradable. Among the bio-based plastics family, PLA (aka polylactic acid) can be one of the most famous members. The raw material to produce PLA is the starch of fermented plants.

Typically, from corn, cassava, sugarcane, or sugar beet pulp. Thus, PLA gets the nick-name of corn plastic. The PLA material will decompose over time in the environment.

With the eco-friendly feature, PLA has gained popularity in many countries. It is likely to make the new trend of single-use plastic bags.

However, there are still issues with bio-based plastics. They could cause environmental impacts from the view of sustainability.

Bio-based plastics are not likely to cause the problem of landfills. But the increasing demand could potentially result in shortages of food. Crops like corn are lifesavers for people in some areas. It is a challenge given the growing population worldwide.

Moreover, to meet the indefinite needs for bio-based plastics, we possibly lose more forests as the cost. And a potential increase in pesticide use which is not good for the environment.

Hopefully, the evolving technology will be able to figure it out asap. At the same time, it is a message for us to reduce the unnecessary use of materials.

Other than adopting recyclable packaging, reusing the packaging is also another eco-friendly packaging idea.

Reusable Packaging

It is not hard to under the term Reusable Packaging from its literal name. And we can find a lot of reusable packaging around.

Also, it highly depends on you to determine whether or not the packaging is reusable.

Now let's take a look at them.

Common Reusable Packaging Products

Plastic Packaging

Yes, it is the plastics again. Despite the bad reputation of White Pollution, even ordinary plastic packaging can be eco-friendly. You can easily do it by using plastic packaging with your eco-friendly packaging ideas.

For example, avoid damage to the box of your new gadgets or the bags of your new clothes. Because they can be containers and protection for some other stuff. Especially when you need to send them out or bring them during vacations.

These easy and handy steps are going to generate excellent eco-friendly results. Since both re-manufacturing, the plastic products and sending the damaged ones are costly to the environment. Sometimes even more than the cost to produce the new products. The lack of oil and the landfill just well witness that.

And your good deeds of re-using the packaging will largely ease the burden of our environment.

Therefore, reusable plastic packaging is also another eco-friendly option. Remember to avoid damaging them and save them for future use next time.

Besides, some paper-based packaging solutions are also reusable now thanks to modern technology.

What packaging to choose?

Now that we have seen the types of eco-friendly packaging, which one to choose then?

We do have some standards to help with your choices.

Eco-friendly Packaging Standards

- The packaging is safe for humans and the environment throughout its life circle

- The technology or way to produce the packaging is clean and does no harm to humans and the environment

- The packaging meets environmental criteria and is affordable by ordinary consumers

In conclusion, what the packaging solution does and how we deal with it is far more important than the material itself.

Sometimes, the ordinary reusable plastic packaging can be more eco-friendly than paper-based ones.

Likewise, if we abuse paper, the damage to the environment possibly will exceed that of plastics.

You will make your eco-friendly choice if you understand the key to eco-friendly packaging ideas. That is, taking the whole picture of the environmental impacts of the packaging solutions. From choosing the material, situations to apply, to the way to deal with them after use.

After that, if you are struggling with your options. The experienced packaging specialists from PrimePac are happy to help. here.

Any other eco-friendly packaging ideas we can do for the environment? Yes.

Eco-friendly packaging ideas #3: what else to do?

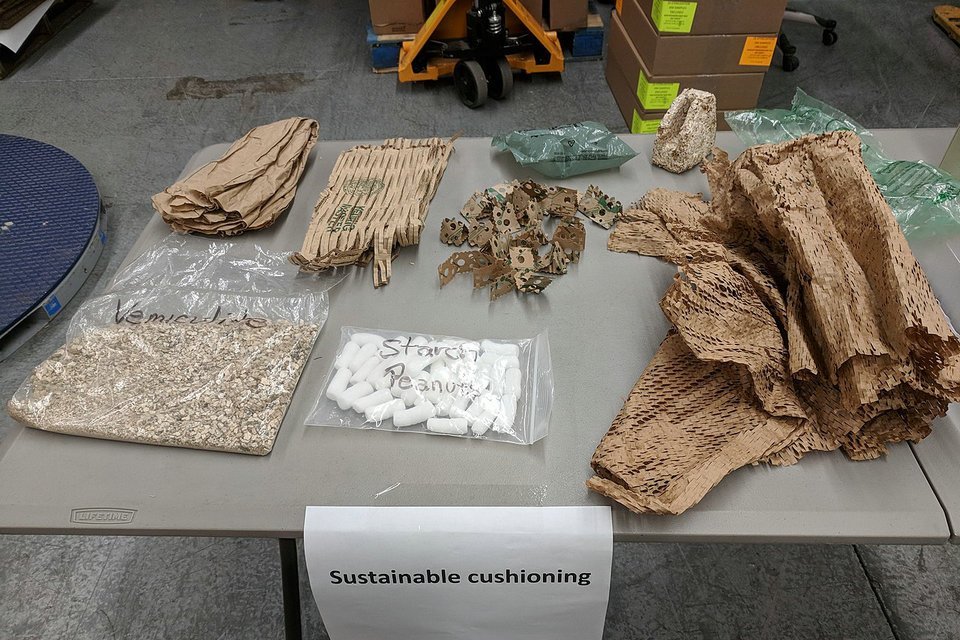

Reduce Packaging

We have discussed before; the abuse of packaging material can cause environmental problems. Even eco-friendly materials would be harmful to the community if used improperly.

Therefore, the demand for packaging is the core of the matter.

Here comes another eco-friendly packaging idea then. Reduce unnecessary use and save the material for packaging. Be a participant in the minimal packaging trend.

But how to reduce the use of packaging while ensuring the safety of the products? We know it might be difficult for you. No worries. You have got us to help you with it.

With in-house knowledge, PrimePac can cater to a diverse global audience. Make use of our network of experienced professionals in the packaging industry here.

ECO-FRIENDLY PACKAGING IDEAS FOR YOUR CREATIVE BUSINESS

Artists and manufacturers are increasingly aware that, just like other larger companies, they need to make thoughtful choices around the packaging they use. Customers demand more sustainable and environmentally friendly packaging, but many designers and manufacturers are also looking for better options to help protect the planet.

The most environmentally friendly packaging option is usually to reuse any boxes, envelopes, and materials that you have in your home. But as your small business grows, this is not always feasible. Although using 100% recycled packaging is good for the environment, it is not necessarily the best choice to ensure product safety, build branding, and communicate design skills.

Therefore, if you want to make your package environmentally friendly, Ahmed from Folksy partner Packhelp has compiled seven environmentally friendly packaging concepts for your creative business...

1. Avoid excessive packaging

This is very simple. By using the wrong size box or packaging,

There is a risk of damaging your product because it will hit the wall.

Need to use more filler materials to protect your products, which will generate more waste.

To avoid this, please choose the packaging that is the most suitable for your product. This does not necessarily mean choosing custom packaging, but be sure to consider the size of the product you are sending, and choose the smallest box or mail in which the product can be safely placed.

Make sure your product fits and fits comfortably to avoid breakage or damage. If you need fillers, please use them in moderation.

Too much packaging or wrong box size, your customer may ask:

Is this store carefully packaging my products?

Are all these packagings necessary?

What can I recycle?

A huge cardboard box full of useless paper will not only increase shipping costs and cause more waste, but it will also seriously affect your brand. By using packaging that fits your product in size, you will convey your values as a brand that cares about the environment, your products will be safer, there will be fewer returns of damaged products, and you will be the planet. All won.

The concept of environmentally friendly packaging for creative companies

2. Embrace the humble cardboard box

Cardboard is a simple and environmentally friendly material. It is biodegradable, reusable, and is made from the recycled pulp in most cases. Cardboard boxes are available in a variety of shapes and sizes and have little impact on the environment.

Double and three-layer cardboard boxes are very strong, which can ensure your products are safe and sound during the entire transportation process. Even if the cardboard boxes are not segregated when they are thrown into the trash can, they can easily decompose in the landfill.

All this means that cardboard is a reliable way to keep packaging clean, cheap, and environmentally friendly.

As we have discussed before, custom printed cardboard boxes or envelopes are a good choice for creative companies because they can form an important part of your brand and help increase your visibility and strengthen your brand image -But when choosing a supplier, look for a product that uses recycled materials and water-based inks, because this adds more sustainability to an already sustainable packaging solution.

When it comes to cardboard, you can also use it out of the box. If you need to send small items (such as jewelry and accessories) that require more protection than plain paper envelopes, but you want a more sustainable alternative to plastic mail and bubble-lined envelopes, then cardboard envelopes are perfect.

If you use Royal Mail, there are also cardboard packaging options tailored to suit the size of large letters or small packages-learn more here.

This means you can get value for money in transportation but in a fully branded way. Or, if you sell your products at craft fairs or through pop-up shops, paper bags are also environmentally friendly.

3. Make your packaging reusable

Monday’s child designed a box that doubles as a toy

Whether we are talking about primary packaging (the packaging around the product), packaging for display on store shelves, or packaging for shipping products, you can reduce waste by making packaging reusable.

Use your creativity here-if you knit children's sweaters, maybe you can design a paper bag that turns into a hanger in some way, or you can design a transport box that can also be used as a pen holder or a paper flower vase?

Or, if you sell handmade skincare products, bath and beauty products, or handmade candles, can you encourage your customers to return their bottles and jars to lower the price for refills?

Be creative! For example, Monday's Child, a British clothing brand for children, designed a box that not only serves as a package, but also as a toy.

Conclusion

The time to complete the eco-friendly mission can belong. But we are on our way to implementing eco-friendly packaging ideas. Join us on the ongoing journey by 2 simple actions.

- Deal with the packaging in eco-friendly ways after use

Do you have more eco-friendly packaging ideas? Tell us here. Your voice matters.

Click to know more eco-friendly packaging solutions with creative designs. Add more value to your brand vision with full-color printing on your eco-friendly packaging.

Food Packaging Market Insight Convincingly

Introduction

The food packaging market is growing with the increasing demand for packaged food. The causes of the growth include the reason below

- The increasing urban population leads to growing consumption of food

- Consumers tend to buy more food with packages today.

- Increased consumption of processed food and takeaways

- Demand for longer shelf-life of the food

As a result, there are chances for the food packaging industry today.

To discuss more on this topic, let’s go deeper into the food market by segments.

Food packaging market today

The global food packaging market size was expected to reach an amount of over USD 300 billion.

On the other hand, the development of food packaging products has never stopped, in order to meet the needs of customers.

The global food packaging market size is estimated at USD 303.26 billion in 2019, growing at a CAGR of 5.2% during the forecast period.

Growing consumer demand for packaged food due to the faster pace of life and changing dietary habits is expected to have a significant impact on the market.

The product offers extended and consistent shelf life, high barrier performance, and safety, thereby contributing to the growth of the market.

Factors such as convenience and the use of high-performance materials are expected to aid the growth of the industry.

The expected increase in shelf life and increased efficiency in preventing contamination of contents is expected to boost the market growth.

In addition, factors such as increasing population, rising disposable income, and shrinking households are also positively influencing the market.

The market in the U.S. is expected to be driven by the increasing urban population, increasing consumption of packaged foods, and the popularity of single-serve packaging. Increasing recycling infrastructure for plastic, metal, and glass is also supporting the market, however, concerns over waste due to improper packaging may hamper its growth.

The evolution of food packaging products today is mainly based on the following features: easy opening, portable to use, and sanitary conditions.

As a result, the requirements for packaging production have become more and more restricted.

Among the various factors, packaging materials play a decisive role.

By 2027, the food packaging market is expected to be worth US$466.91 billion, with a compound annual growth rate of 6.17% during the forecast period (2021-2027), and the market value in 2020 is US$310.8 billion.

In order to extend the shelf life of food and ensure the protection of travel and door-to-door food, the market plays a vital role.

Good food packaging can protect food and attract more customers, thereby increasing market share in the global market.

The increase in changing lifestyles has also led to market growth in the global market.

Today, people prefer processed foods or packaged foods because they can be stored for a long time and are easy to use.

With the transition from rural to urban areas, the market is expected to grow further.

COVID 19 analysis

The situation of the COVID 19 global pandemic has adversely affected people’s lives. People must deal with the financial crisis and health problems at the same time. The outbreak of the global pandemic pushed the economy into a forced recession, which led to financial crises in various countries. The situation during the lock-up and post-lock-up period has led to the closure of multiple manufacturing units around the world, resulting in a decline in revenue and a decline in profit margins.

It is expected that during the forecast period, the market will recover from this global epidemic before the end of the second quarter of the following year.

Some companies even shut down their businesses permanently. In this difficult period, with the help of various government policies in favor of them, companies are slowly recovering from losses.

Competitive landscape

The most prominent main players in the food packaging market in the global market are as follows:

Amcor Limited (Australia)

Coveris Holdings S.A. (Luxembourg)

The Smurfit Kappa Group plc (Republic of Ireland)

- du Pont de Nemours and Company (United States)

Mondi Plc (Austria)

Bemis Company, Inc. (United States)

International Paper Company (United States)

- Smith Company (UK.)

Silgan Holdings Inc. (United States)

Rock-Tenn Company (United States)

These most famous market participants establish new units in potential markets through cooperation, mergers and acquisitions and cooperation, new product development, and development in the production process, thereby using various strategies and policies to expand their customer base.

Market dynamics

Driver

The market is accelerating due to various factors, such as changing trends in professionalism and material advancement, changing trends in processed foods, and adopting various strategies that contribute to the growth of the global market.

Due to the continuous advancement in the technical field, the growth of the market is increasing. Now, the ever-changing lifestyle and more demand for packaged food have led to an increase in the demand for the market in the global market.

Chance

Due to various growth opportunities in the global market during the forecast period, the market is growing at an alarming rate.

Due to the use of antibacterial packaging technology that helps to extend the shelf life, food packaging technology continues to improve packaging foods, even perishable foods. In addition, due to increasingly fierce competition strategies among major players in emerging countries, the market shows various growth opportunities during the forecast period.

Constraint

The global market is growing rapidly, but certain factors limit the growth of the global market, such as fluctuations in the prices of raw materials used in the food packaging industry.

Therefore, higher raw material costs hinder the growth rate. In addition, the main material used in the food packaging industry is plastic, which is a non-biodegradable material.

The governments of various emerging countries have issued strict regulations on the use of the market to limit the growth of the packaging market.

Value chain analysis

Due to the various benefits associated with it, the market is growing at an alarming rate. For example, it can protect food from external dust and extend the shelf life of food. Packaged food also improves hygiene factors.

Packaged food also contains all the important information about the product’s manufacturing and expiry date, as well as a list of ingredients, which will also help raise their awareness of what they eat.

Market segmentation

The food packaging market in the global market has been divided according to applications and types.

Food packaging market by materials

Generally, popular materials for food packaging products today are mainly

- Paper and board

- Rigid and flexible plastic

- Glass

- Metal

1. Paper and board on the current food packaging market

Paper-based packaging materials have become one of the favorite packaging products. As a matter of fact, more and more people start to adopt paper and paper-based packaging products. After all, paper bags and boxes get their reputation as the biodegradable solution with the household name.

And because of that, many expect a growth of the packaging market of paper and paper-based material.

The segment generated a revenue share of 31.9% of the total food packaging market in 2019.

2. Rigid and flexible plastics on the current food packaging market

For a long time, the packaging products of plastic materials play a key role in the packaging industry. Although the traditional plastic packaging materials are not as eco-friendly as the paper-based packaging materials. Still, they are on the service line in many aspects today. After all, the low price brings them a bunch of fans, which makes them popular until now.

Meanwhile, plastic packaging products have unique advantages over others. You can tell them with your own experiences, such as excellent sealing capacity and high water-proof performance.

Moreover, the application of eco-friendly technology has extended the life circle of plastic materials. With the feature of recycling, biodegradability, and compostability.

Want to know more about biodegradability and compostability? Also, read More about Biodegradable Packaging.

All these factors cause another rapid growth in the plastic food packaging market.

3. Glass on the current food packaging market

Glass packaging for food is commonly seen almost everywhere, from the shelf in a supermarket to the compartment of the refrigerator at home. The popularity results from the high-performance of fresh-keeping ability combined with its non-corrosive nature. Also, glass material is recyclable and non-sensitive to chemicals.

All these features make it a desirable packaging material for food preservation and direct food contact.

Therefore, an estimation of USD 43.5 billion by 2027 for the glass material segment.

4. Metal on the current food packaging market

Metal packaging for food? It might look weird at first glance. But think twice, you will probably find them common and familiar.

Usually, metal packaging is widely used for canned food such as meat, fish, and fruits.

There are times you worry about the life span of the food, or just too busy to grab the ingredients for cooking from the market. In these cases, a couple of canned food helps you from starving your stomach.

Metal packaging stands out among the others with the ability to extend the shelf-life of food products and preserve the nutrition of food.

Hereby the market growth of the metal packaging segment, not so fast as that of other segments above though.

In conclusion, the growth of the paper packaging market takes first place in the material segment.

Applications

If you look at the packaging market by the segments of applications. You probably find out the wide usage of packaging solutions in the industry below.

- Bakeryand Confectionery

- Dairy products

- Fruits and vegetables

- Meat and seafood

1. Bakery and Confectionery

Bakery and confectionery require packaging with moisture-proof material with high-level performance. Because moisture is the killer of bakery and confectionery products, which will largely shorten their shelf life.

At the same time, the price is another key factor to consider. Flexible packaging has excellent moisture-proof performance. Lower prices over paper and metal materials combined with the feature of lightweight.

Above all, flexible packaging takes an advantaged place over the other packaging solutions.

2. Dairy products

Dairy products can be a necessity for every family. The constant demand for dairy products boosts the growth of the packaging market.

On the other hand, the designs of the packaging have become more and more attractive to customers. Sometimes, you may pick up a bottle of milk or a piece of yogurt for their appealing packaging.

And all these deeds definitely contribute to the market growth of packaging products for the dairy industry.

3. Fruits and vegetables

The segment of fruit and vegetable packaging has been growing recently. An important reason among the others can be the rising awareness of health.

To get more vitamins in your daily meals, you want to fetch some fruits in the supermarket. And you want them packed in a clean bag best eco-friendly materials. Because you want your food preserved in a place with protection rather than being exposed for hours in the public area.

Now, you realize that you are one of the contributors to the growing market share for fruits and vegetable packaging.

4. Meat and seafood

The increasing demand for meat and seafood has led to the growth of the packaging market for this segment. As well as that of dairy products, you probably need them every day unless you are a vegetarian or vegan.

Moreover, meat is one of the things you usually find in popular healthy eating habit suggestions.

For all these reasons, the packaging market for meat and seafood grows at a rapid pace.

Regional diversity

- Asia-Pacific

- North America

- Europe

1. The food packaging market in Asia-Pacific

The Asia Pacific is estimated to be the largest market with 37% of the total market share in 2019.

Among the countries in this region, China is the largest contributor. Because Chinese consumers have more purchasing power today, as a result of the increase in the middle-class population.

Meanwhile, the Indian market is growing the fastest due to the increasing usage of food packaging products.

2. The food packaging market in North America

When it comes to North America, the packaging market growth is more a result of the thriving retail industry. And the large consumption of packaged food is another reason for the market growth.

3. The food packaging market in Europe

The European food packaging market shows a positive pose expectedly. Although the domestic market has reached a saturation level.

Export business in the region will pretty much propel another growth of the packaging industry. One of the key reasons is the free-trade policy in Europe.

Paper food packaging – the trend

As a result of various factors, the paper packaging market has been growing at a rapid pace.

Among the other causes, the prevailing habit of buying eco-friendly products is the key one. More and more people and industries start to use and produce paper food packaging.

Why? Because paper food packaging has a lot of benefits. Being friendly to the environment is the critical one among the others.

1. Paper packaging is eco-friendly

For a long time, the overuse of plastics has greatly damaged the environment. And the pain still continues today. You can easily find the evidence in just a bit of time. As a citizen in the village of earth, the environment matters to every one of us.

Honestly, our living conditions could have been better without the abuse of plastic at a time. But fortunately, the awareness of environmental protection has become increasingly popular with society.

As a result, more and more consumers are looking for ways to improve our environment. They try their best to seek eco-friendly products and reduce the use of non-biodegradable materials. The adoption of paper food packaging is the witness.

2. Paper packaging is multi-functional

You can use paper-based packaging in many cases today. This is another reason to use it as an alternative to plastics. Paper packaging might not be so popular as it is today because it could easily get damaged. But thanks to modern technology, paper-based packaging has become increasingly strong and durable. You probably find your cardboard box still stands upright after handling several heavy loads.

Also, they are recyclable. After the main paper material finishes its missions in the frontline, the leftover pieces continue the cycle. Scrap paper is the raw material of a variety of products such as fiber-board, paper sacks, wrapping paper, and more.

Moreover, many companies are adopting and developing paper-based bottles as containers for coffee, soft drinks, and other beverages. You can easily find paper coffee cups when you try to get some coffee in many coffee shops today.

At the same time, the usage of paper bags to keep dry foods has become prevalent such as coffee, tea leaves, snack food and nuts, cookies and candy, and spices. Because paper-based materials can keep the freshness of the food by “keeping their breath”.

All in all, this trend of paper packaging continues and could be a competitive alternative over the other packaging solutions.

3. Paper packaging is lighter

Due to its lightweight, shipping a load of goods packed by paper packaging requires much less energy.

With the contribution of advanced technology, paper packaging today can handle more situations than it used to be which enables a paper container to stay longer in the service line and offers better protection for the goods. Therefore, less demand for a second container to load the cargo.

In other words, you can save your shipping cost and keep more money in your bank account.

You will find more benefits of the paper packaging solution as the trend continues.

Conclusion

Thanks to the growing trend of the global packaging market, the packaging industry has got more chances. Companies dealing with paper packaging and other eco-friendly are likely to earn the most benefits.

Despite the constant change, the market winners always share the characters in common. They never stop their pace to develop and show more care in our community.

In terms of environmental protection, PrimePac continues to do with the best effort.

Paper food packaging in PrimePac

We contribute by the continuous investment in the production line of paper food packaging. PrimePac has established a reputation among our customers through creative designs and the application of modern technology.

Click to know more about our paper packaging products. Customers adopt our paper-based packaging solutions in various applications. Food & beverages, health care, and pet care are the most common ones.

Popular Custom packaging trends in Australia 2020

Introduction

The custom packaging market is surging rapidly these days. As a result of increasing consumption throughout the world. And the popularity of packaging trends in Australia has greatly fueled the growth of the global packaging market. The custom packaging market in Australia is not an exception.

Today, we are going to talk about custom packaging trends in Australia.

Custom packaging trends now

As a matter of fact, products with nice-looking packaging comes with better quality. A study about packaging trends in Australia reveals that 68% of consumers believe it. Consumers are willing to spend more money on well-packaged products.

The Australian plastic packaging market is valued at USD 356.2 million in 2020 and is expected to reach USD 442.5 million by 2026, growing at a CAGR of 3.8% during the forecast period (2021 to 2026). Polyethylene terephthalate (PETE or PET) is commonly found in most plastic packaging products in the country. Macquarie University says Australians buy about 118,000 tons of plastic beverage bottles each year, despite 250 rigorous inspections of tap water by Australian water companies. Based on such projections, existing packaging manufacturers can be seen to have increased their ability to meet the scale of domestic demand and packaging trends in Australia.

What kinds of packaging products are making the trend today? Keep reading, we have a list for you.

Generally, the following packaging products are the key players in today's custom packaging market.

- Flexible Packaging

- Personalized Packaging

- Digital Print Packaging

- Recycled Packaging

- Clean Label Packaging

And we are going to talk about them one by one.

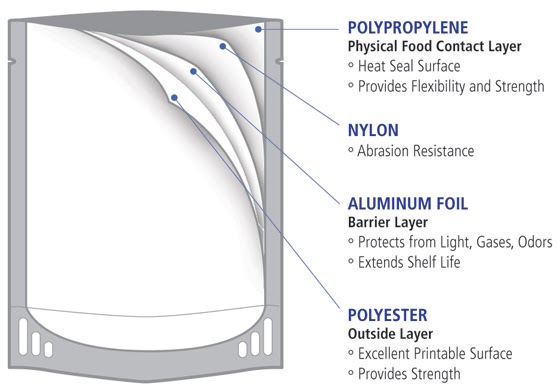

1. Flexible Packaging

In packaging trends in Australia, Flexible packaging gains its popularity with unique advantages over the others. Products with flexible packaging are easier to store and care about.

Another reason that makes it so popular is less material consumption.

Moreover, products with flexible packaging usually take less space. As we all know, the more space it costs, the more money you pay. Just look at the real estate market today.

When it comes to shipping and storage, when you save the space, you save your money!

2. Personalized Packaging

Personalization can be one of the words you hear the most in the retail business today. The retail business stands in front of a place dealing with customers. No need to mention the importance of it provided the growing consumption for packaging trends in Australia.

And personalization is now a defining factor for high sales in many businesses. Famous brands have never stopped their effort in customization to seize the trend. See the various shapes of the packagings and the printed lines on it? There you go.

3. Digital Print Packaging

As mentioned above about packaging trends in Australia, personalization has become the pet of the consumers. Digital printing packaging largely shares benefits.

Why? I am sure you can find the answer by yourself. Just think about how the lines get their marks on the packaging for packaging trends in Australia.

There are times you want to surprise your love with magic words in packaging trends in Australia. And you want them to appear together with a gift in beautiful packaging. In this case, the digital print packaging just helps you out.

All this printing demand for personalization leads to the digital printing packaging trend in Australia. The growth of digital presses has far preceded conventional presses as a result.

4. Recycled Packaging

While you find it fun to personalize your packaging, being friendly to the environment can be a plus. The popularity of environmental protection helps recycled packaging get its place in the packaging trend.

More and more people like you are showing their care for our environment. Actions in reducing waste and pollution by disposable materials prevail today. Recycling is one of the solutions.

Recycled Packaging seizes the custom packaging trend in Australia by using recyclable materials, and reducing the use of harmful substances in packaging.

Amcor, for example, the Australian global leading company in the packaging industry. Now, the company focuses on providing packaging products of recyclable and reusable materials.

In January 2018, Amcor has pledged to develop all its packaging products to be recyclable or reusable by 2025.

Meanwhile, advancements in modern technology are making recycling easier and easier.

5. Clean Label Packaging

Honesty has always been fundamental in the business world. This leads to the packaging trend in Australia of clean labeling.

Clean label packaging comes with the idea to provide transparent information to the customers. You might find some labels with full detail of the ingredients of the product. For example, you probably found what makes the medicine on its packaging. And its side effects as well.

Studies revealed that consumers want to know what their food contains. And 50% of them would like to find out the answer by scanning the packages. In this case, a clean label just eases them. Because they will not have to use their phones particularly when the network doesn't work well.

If you are one of them, the prevalence of clean labeling might not surprise you in the custom packaging domain in Australia, as a result.

Finished all the content above? Congratulation! You probably have found it out. Nowadays, more and more sellers use the package as part of their marketing strategy meeting the packaging trends in Australia.

No kidding, product packaging can help you boost your sales!

If you want to know more, just keep reading.

Consumers care for the packaging

Today, consumers care more about packaging than ever. If you value the product quality and agree that quality is the core successful business, don't save your bucks on the packages.

After all, the product packaging is another defining factor of the quality of the product as a whole.

The packaging is the protection of the goods

You don't want your custom crystal watch to come damaged before you enjoy its beauty. Ignore that if you just generously accept that imperfection is another way of beauty.

Damages can easily happen without good protection, especially when your goods come from another place.

As a result of the rapid growth of eCommerce, shopping overseas has been a fashion. Your goods probably travel a long distance before delivery to your hand. Some journeys are long enough to go around the world.

In this case, you surely realize the importance of safe shipment. After all, it is the very first guarantee of your product's safety meeting the packaging trends in Australia.

Besides, the packaging can directly affect your sales performance.

The packaging is the face of your brand

You are looking for 2 necklaces for your girlfriend. They both come with shining quality. And the prices of both do not show much difference. It is really hard for you to make a decision. I know.

But later, you find one comes with decent packaging. And the other one just in a small little paper box. You probably find this box easily everywhere you walk around. Now, what is your choice?

I guess the difference is obvious between the two, after the comparison of the packages.

There's no need to mention the effect of appearance on the user experience.

Therefore, think twice when you choose the packaging products for your goods.

Not that you understand the importance of custom packaging, how to make your brand distinguishing by packaging solutions then? No worries, the advice is below.

How to boost your sales in the custom packaging trend

1. Make it beautiful

Do you believe in love at first sight? It truly happens. A good-looking design will definitely help improve your package.

So, the first piece of advice - make it so beautiful as art that your customers will take photos and share on SNS. If you still remember, Obama got a bunch of votes by the campaign on SNS. And he finally won the election.

Once your packaging is beautiful enough, you will find a way to the trend. After all, getting the traffic is the first step of trending the business.

2. Go green and eco-friendly

Not that the eco-friendly products are trending the way of custom packaging in Australia. It's wised to join the trend. It also helps establish your reputation in the community by being responsible for our environment.

Your brand draws attention when you care more about society when making money. Bonus points to brand awareness when customers recognize your efforts in the good deeds for the public.

So, choose a packaging solution that adds ecological value to your business. As the other big brands get eco-friendly elements into their product cycle, you will earn your traffic by being part of the circle.

3. Get your packaging into the hits

Remember the lines on the bottle label of a coke? And the sweet words appeared together on the box of your necklace. Packaging can convey important messages as you know.

Invite digital printing to be part of the game, personalize your boxes along with the hitting topics on google. Look at the loving eyes of the customers. Your seasonal promotion is going to hit soon!

4. Make full use of your packaging

Under the popularity of being eco-friendly in the packaging market. Most people would not mind using packaging with recycled material, as long as the quality is good enough. After all, this is one easy thing to do but a contribution to reducing the carbon footprint.

Get packaging by recycled material into your packaging solution. And encourage your customers to make more use of your packaging. Both of them show your actions in the eco-friendly trend. Also, give more exposure to your branding.

5. Add values to your label

Since clean labeling is trending in the business, you might as well play along.

Where there is space, there is the way. Enlightenment by the thriving market of real-estate. And so is your packaging.

Make use of the space on your packaging. Tell your customers more about the products. So, they feel more of your care.

Like you fetch some material to cook for your dinner. The vendor tells you where they grow the vegetables and how to cook on the packaging. And, I could see your truly beautiful smile for it.

Conclusion

In conclusion, the 5 stars in the custom packaging market are trending the game. They are flexible packaging, personalized packaging, digital print packaging, recycled packaging, and clean label packaging.

Along with the custom packaging trend, there are 5 pieces of advice. Hopefully, they will help you seize the trend and make some money taking advantage of the growth of the custom packaging market.

Last but not least, we have prepared a dish of packaging solutions for your reference.

PrimePac Australia is more than willing to help you out with your packaging solutions.

The Truth About Polypropylene Woven Bags Packaging in 2020

The packaging is usually divided into two categories: one is to promote market sales and the other is to facilitate loading, unloading, storage, storage, and transportation purposes, called industrial packaging. This article will focus on packaging made from polypropylene-pp woven bags. This article first describes the concept of polypropylene woven bags, then outlines its advantages and uses, and then analyzes the dynamics and demands of the polypropylene woven bag market, and finally draws conclusions.

Polypropylene (PP) is a thermoplastic resin made by polymerizing propylene. Polypropylene woven bags also include copolymers of propylene and a small amount of ethylene. Polypropylene is usually a translucent colorless solid, odorless and non-toxic. Due to the regular structure and high crystallization of polypropylene, its melting point is as high as 167 ° C. Its finished products can be steam-sterilized is its outstanding advantage. Its density is 0.90g / cm3, which is the lightest general-purpose plastic. Its strength, rigidity, and transparency are better than polyethylene.

Pacific Bags Australia has a wide range of sizes of woven polypropylene bags. These bags are an excellent solution for packing 30-50 KG of dry material. These pouches are made from a woven polypropylene fabric that is strong and resistant to punctures. PP woven sachets are available in laminated or non-laminated forms depending on the material. This material is a commonly used material, which is a translucent material in polypropylene woven bags. When using this material, it will not produce any poisonous effect, and it will not have any odor. We can process pp into plastic woven bags, which are widely used in the packaging industry. When processing this material, woven bag manufacturers need to burn it to its melting point, 167 degrees Celsius, so it will have strong heat resistance when it is used later. Steam will also be used for disinfection so that all products will not be damaged during use. It is worth mentioning that the products made from pp have a very small density, so the product is very lightweight and more convenient for us to use. Moreover, the plastic woven bag made of this material also has high strength and corrosion resistance, so as a popular packaging product now, it is not only lightweight and durable but also can be recycled after use; it is truly a popular packaging product.

Advantages of polypropylene woven bag

#1. Heat resistance of polypropylene woven bags:

The heat resistance of polypropylene is stronger than that of polyethylene. Generally, the melting point of polypropylene is about 40% -50% higher than that of polyethylene, about 160-170 ° C, so the product can be sterilized at a temperature above 100 ° C. It does not deform at 150 ° C under the condition of no external force. Similarly, in the field of ordinary packaging bags, polyethylene packaging bags are more suitable for use below 90 ° C, while polypropylene packaging bags can also be used at relatively higher temperatures.

#2 Rigidity and tensile strength of polypropylene woven bags:

Polypropylene is mainly characterized by low density, better mechanical properties than polyethylene, and outstanding rigidity. For example, polypropylene has gradually started to compete with engineering plastics (PA / PC) and is widely used in Electronic appliances, automotive fields. In addition, polypropylene has high tensile strength and good bending resistance. It will not turn white when it is bent one million times, which also provides clues for us to identify polypropylene products, and also becomes a hidden mark for the recycling classification of products.

#3. After decades of development, polypropylene woven bags have undergone great changes in appearance, quality, and use.

In appearance, the pp woven bag woven with mixed-colour flat silk looks more beautiful and has a certain three-dimensional sense. In terms of quality, the quality of current pp woven bags is subject to national supervision, and the quality must meet the unified national standards before it can flow to the market. In terms of use, pp woven bags have been used not only for transportation of food and grain or construction of dams but also for shopping and shopping as a tote bag, which is more environmentally friendly. At the same time, some stores also use it as a packaging bag.

Applications of polypropylene woven bag

1.Agricultural product packaging and replacing paper cement packaging bags

Currently, due to product resource and price issues, 6 billion woven bags are used in cement packaging in China each year, accounting for more than 85% of bulk cement packaging. With the development and application of flexible container bags, plastic woven bags are widely used in marine, transportation, packaging, and agricultural products. In agricultural product packaging, plastic woven bags have been widely used in aquatic product packaging, poultry feed packaging, and farm covering materials. Common products: feed woven bags, chemical woven bags, the putty powder is woven bags, urea woven bags, vegetable mesh bags, fruit mesh bags, etc.

2.Food packaging

In recent years, rice, flour, and other food packaging have gradually been packed in pp woven bags. Common woven bags are rice woven bags, flour woven bags, corn woven bags, and other woven bags.

3.Tourism and transportation

Temporary tents, parasols, and various travel bags have plastic woven fabrics. Various tarpaulins are widely used as covering materials for transportation and storage, replacing cotton tarpaulins that are prone to mildew. It is also widely used in fences and nets in construction. Common products: logistics bags, logistics packaging bags, freight bags, freight packaging bags, etc.

4. Daily necessities

Working, farming, shipping, and gathering, no one does not use plastic woven products, in stores, warehouses, homes, plastic woven products are everywhere. The padding material for chemical fiber carpets has also been replaced by plastic braids.

5. Anti-flood materials

The construction of flood resistance, dams, riverbanks, railways, and highways is also indispensable for woven bags. They are anti-woven bags, drought-proof bags, and flood-proof bags!

6.Special woven bag

Some industries require special woven bags, such as carbon black bags, which are not usually used due to special factors. Carbon black bag’s biggest feature: sun protection. That is, the carbon black woven bag has a stronger sun protection ability than the ordinary woven bag.

The ordinary woven bag cannot withstand long-term exposure to the sun. There are also anti-UV woven bags: with anti-ultraviolet function, anti-aging function, etc.

Market dynamics of polypropylene woven bag

According to research in the “Polypropylene Woven Bag and Sack Market”, countries are passing legislation prohibiting the use of plastic bags and imposing taxes to offset the environmental impact of the production and disposal of plastic bags. Although the materials used in polypropylene woven bags and sacks are not completely biodegradable, these bags can be reused and recycled, so the environmental hazards associated with polyethylene (PE) have led to the use of PP woven bags and sacks as more sustainable s Choice. In fact, with the steady increase in demand, the production of polypropylene woven bags and sacks is becoming a profitable small business. According to the British “Daily Mail” report, in the field of fast-moving consumer goods, the expansion of the retail industry has led to a surge in retail outlets, which will continue to bode well for the growth of the PP woven bags and sacks market.

Previously, the initiative on the ban on plastic bags has been widely accepted by countries in the Asia-Pacific region. Therefore, the Asia-Pacific region (excluding Japan) led by the fast-moving consumer goods industry has naturally become the backbone of the global PP woven bag and sack market. The middle-class population in the region also Is proliferating. In addition, most of the polypropylene woven bags in the Asia-Pacific region are mainly concentrated in China and India.

The market demands of polypropylene woven bags.

As the demand for packaging products continues to grow, major manufacturers in the Asia Pacific region realize that the needs of consumers and end-use industries are constantly changing. They will focus on the production of PP woven bags and sacks, and launch a variety of products. Strive to be a reliable manufacturer of custom woven bags. They export more than half of their products to the United States, Canada, the UAE, Australia, Germany, and the United Kingdom. These manufacturers are also accelerating their entry into Eastern European and South African polypropylene woven bags markets.

From the perspective of value and sales volume, the popular open-mouth bags dominate the PP woven bags and sacks market, which together account for more than 50% of the market share. Due to cost, strength, and environmental reasons, laminated polypropylene is woven bags, and sacks are more favored than non-laminated polypropylene woven bags and sacks, accounting for 60% of global sales. According to Fac.MR (India, Pune) research, the PP woven bag market is expected to achieve a compound annual growth rate of 4% between 2018 and 2028.

Since most thermoplastics are petroleum-based and non-biodegradable, they will not rot, decompose, and will not be affected by microbial degradation. The threat of resource consumption by petroleum products prompts the industry to develop and increase recycled thermoplastic materials. Plastic has become an inevitable trend of sustainable development. In addition, the growing demand for thermoplastic materials in various applications in the electronics, automotive, and manufacturing industries will also promote the development of the global recycled thermoplastic market.

The Asia-Pacific region is the largest market for the production of polypropylene raw materials and recycled thermoplastics because of the huge demand for polypropylene products from the fast-moving consumer goods, packaging, and construction industries in the Asia-Pacific region, and the increasing awareness of the strong market potential of the polypropylene plastics recycling industry in the society, Driving the area to lead the world in the demand for recycled polypropylene plastics. Europe also has a considerable share of the global market for recycled thermoplastics. The increased use of recycled thermoplastics in the automotive industry, coupled with strict recycling regulations, is expected to drive growth in the European region over the forecast period in polypropylene woven bags.

Conclusion:

The applications of thermoplastics are diverse, but the properties of polypropylene make it more widely used. Especially with the environmental protection consciousness, people’s awareness of sustainable development and renewables is gradually increasing.

Because polypropylene woven bags has many outstanding advantages, the plastic woven bag industry has a preference for polypropylene from raw material suppliers to woven bag manufacturers to end consumers. In the past ten years, polypropylene’s global plastics market share has increased significantly.

Waste classification is becoming more and more perfect, and the recycling and utilization of plastic bags have also been put on the agenda by many countries. We always produce plastic waste in our daily life, and the various environmental pollution caused by this plastic waste is getting more and more attention. Therefore, the use of recycled polypropylene woven bags is a general trend, and its market prospects will attract much attention.

About PeimePac

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

Network

With our team in China and Australia working as one, we reduce inefficiency so that you deal with one streamlined team from manufacturing right to delivery.

Service support team located in Guangzhou, the manufacturing hub of China, providing rapid response, and local industry knowledge. Warehouse and 3PL network located in Sydney, to provide rapid distribution, and delivery to your customers.

Focus on Biodegradable Packaging Market

Beverage and food packaging materials are the industries that waste the most energy and resources. The annual production demand for packaging materials is as high as 67 million tons, which not only consumes energy resources but most poses a serious threat to the ecological environment. In order to better protect the environment, therefore, biodegradable packaging came into being.

Degradable plastic refers to plastics with a certain of additives (such as starch, modified starch or other cellulose, photosensitizers, degradants, etc.), which have lower stability and are more easily degraded in the natural environment. Its application can effectively alleviate ecological and environmental problems and reduce the waste of resources.

After this article gives an overview of the biodegradable packaging market, it mainly explains the types of degradable packaging materials and summarizes the factors driving this market development, and then describes the current market size and forecasts of the market’s future. Finally, it points out various challenges encountered by the degradable packaging industry in the development process.

Market review of biodegradable packaging

Companies around the world are adopting sustainable packaging solutions, including the use of biodegradable and recyclable paper. According to statistics, paper packaging solutions will dominate the market in 2021, so the use of paper in packaging materials will increase. Many companies that provide paper packaging solutions focus on biodegradable products to attract consumers. Industry leaders are working to provide complete biodegradable packaging solutions to gain an expanding market.

Compared to end-user consumers, the demand for these packaging solutions is considered high in the industry because it eliminates the need for attractive packaging in industrial solutions. Overall, the market is expected to show strong growth over the forecast period. However, recycling remains one of the main trends observed in the industry.

Although paper products are biodegradable, the process has been determined to be inconsistent in landfills due to the presence of external elements. The impact of the landfill is attracting the attention of municipalities. Therefore, as there are no added artificial elements, governments and organizations are promoting the recycling of disposable landfills, and biodegradable packaging is highly recyclable.

The ability to use biodegradable materials in the packaging industry is increasing due to the growing demand for recyclable materials in end-use industries such as personal and home care, food and beverage, and pharmaceuticals. This phenomenon, in particular, is supported by growing consumer awareness of their interests. In particular, in the food packaging industry, biodegradable packaging materials have been widely used to promote green living around the world, essentially by reducing waste. Several regional and global regulations to reduce ecological damage from overflowing landfills provide an amazing incentive to adopt biodegradable packaging materials. In addition, in recent decades, continuous efforts to adopt sustainability in sustainable development have led to widespread demand for such packaging materials.

Biodegradable packaging material types

Traditional packaging materials include paper, cardboard, plastic, metal, glass, wood, and other materials. Green packaging materials mainly refer to materials that have good use performance, or function, have little pollution to the ecological environment, are easily degradable, easy to recycle, have high recycling rates, or can be effectively recycled in the environment without causing harm to human bodies.

The biodegradable packaging market was valued at $3.97 billion in 2018 and is expected to reach a market value of $10.3 billion by 2024, with a CAGR of 17.04% during the forecast period from 2020 to 2024.

Biodegradable packaging has been widely used in the packaging industry because of its ecological friendliness. With the rising price of crude oil and issues related to petroleum-based plastics (such as disposal and effective waste management), the concept of using biodegradable plastics as an alternative to various applications such as FMCG, hospital, manufacturing is increasing, which is driving the development of the market.

The key point of green packaging is whether the packaging materials are reusable and degradable. Biodegradable materials such as bioplastics and paper are widely used in the packaging industry because of their sustainable properties, appearance, and properties.

Biodegradable packaging is different from traditional non-biodegradable packaging in terms of raw materials, production technology, applications, and composting. Biodegradable packaging materials are used for all levels of packaging, such as primary, secondary, and tertiary packaging

1.Driven by sustainable development

Degradable materials have less impact on the environment, meet the requirements of sustainable development, and can effectively solve problems such as environmental crises. Therefore, the demand is constantly growing, and biodegradable packaging products are increasingly used in various industries. Since most of the materials used in this package are natural and can be degraded without a catalyst, this package has a wide range of applications in the food and beverage industry.

Many industries and governments have taken steps to reduce material waste and reduce their environmental impact. Companies such as Unilever and P & G have promised to switch to natural packaging solutions and reduce their ecological footprint (mainly carbon emissions) by 50%, which is one of the factors driving the use of biodegradable packaging in various industries. More and more innovations, such as automatic and smart packaging solutions in the industry, are being extended to end products.

2. Consumer preference driven

One of the key factors contributing to the growth of this market is the consumer increasingly focus on environmentally friendly packaging. As consumers’ focus shifts to a healthier life, consumers are more inclined to choose environmentally friendly plastic bags and environmentally friendly food packaging bags, and their demand for natural, environmentally friendly and green products is also increasing. This shift in consumer behavior is forcing major plastics manufacturers and packaging manufacturers to continually explore the possibilities for the application of biodegradable polymer materials.

3. Legal supervision

Because the solid waste formed by non-degradable packaging materials is very harmful to the environment, many countries (especially developed countries) have formulated strict regulations to reduce waste and promote the use of biodegradable packaging materials. It is reported that developed countries and regions in Europe, the United States, Japan, and other countries have successively formulated and introduced relevant regulations to restrict the use of non-degradable plastics through measures such as local bans, restrictions, compulsory collection, and collection of pollution taxes, and vigorously develop new biodegradable materials in order to protect the environment and the soil.

Among them, France introduced a policy in 2005: all disposable plastic bags must be biodegradable after 2010. Now that Cameroon has joined this camp, it can be seen that non-environment-friendly packaging materials will continue to run into obstacles in the future development market. Correspondingly, environmentally friendly packaging materials will usher in a golden period of development. These materials are usually made from renewable raw materials such as starch and cellulose. Biodegradable plastic can be decomposed into compounds by the enzymatic action of microorganisms, into CO2, methane, and water.

Market size and forecast of biodegradable packaging

Data show that in 2017, the size of biodegradable materials in the packaging market was 81.01 billion US dollars. The global packaging market’s demand for degradable plastics will reach 9.45 million tons in 2023, and the market size will reach 113.55 billion US dollars. In the forecast period (2018 (-2023), the compound annual growth rate is 5.9%.

The market for degradable plastic packaging is huge, and the demand for food packaging accounts for more than 70% of the market for degradable plastic packaging, which is self-evident. Relevant research also emphasizes the latest development trends. Under the new situation, “green packaging” will be more and more widely used in the logistics industry.

This requires logistics companies that provide packaging services to carry out green packaging transformation, including the use of environmentally friendly materials. Improve material utilization, design folding packaging to reduce empty load rate, establish a packaging reuse system, etc .; promote the production department to adopt packaging that is as simple as possible and made of degradable materials; in the circulation process, various measures should be taken realize the rationalization and modernization of packaging.

A previous IHS Markit report showed that the global market value of biodegradable plastics in 2018 was more than 1.1 billion US dollars, and the market value is expected to reach 1.7 billion US dollars by 2023. The report highlights the application of these biodegradable material solutions in various regions and industries.

Challenges of biodegradable packaging

At present, there are still some problems in the development and application of biodegradable polymers:

# Due to issues such as corporate interests, the popularity of degradable plastics is not smooth.

At present, China’s degradable plastics are still in the stage of publicity and promotion, and the degree of marketization is not high. However, the promotion and application of green packaging is not easy. In industries mandated by the state, such as disposable plastic cups, lunch boxes, cutlery and other daily plastic products in the catering industry, the proportion of using degradable plastics is relatively high, while in industry and agriculture, the use of degradable plastics is relatively low. . As Zhang Jindong, chairman of Suning Holdings Group, said during the two sessions this year, promoting green packaging in the logistics industry is a systematic project, from the use of green recycling products to the establishment of a packaging recycling system and the reduction of express packaging consumables. It requires not only the “marriage” of the government and enterprises, but also people’s deep-rooted green ideas in daily life.

# In addition, the market price of degradable plastic is 2-3 times that of ordinary plastic products.

If it is successfully sold, the profit level is 10%, and the profit level of ordinary plastic is 1% -3%. Although the profit level is high, the current sales resistance of degradable plastics is relatively large. The first is higher costs, larger capital occupation, and poor acceptance of downstream companies. The second is that degradable plastics have a certain shelf life. Sales are not smooth, and the risk of loss for the company is greater.

# The degradability of the polymer

It will inevitably damage the durability of the product, and it will also reduce its mechanical properties to a certain extent, thereby limiting the application range of the biodegradable polymer.

As far as the results of current research and production technologies are concerned, it still takes a long time to make them universally available. The low cost of development, time-degrading, and highly efficient bioplastics is the main direction of future research in this field.

Nevertheless, it is encouraging to see that changes are taking place, and relevant companies and institutions are working hard to carry out innovative research and development and exploration, especially in the application of packaging materials, plastic films, medical materials, and other fields. A revolution with many bright spots around green packaging is ongoing

Conclusion:

To sum up, in the long run, increasing domestic environmental awareness will broaden the use of degradable plastics; increasing demand for environmentally friendly materials abroad will increase exports of degradable plastics, and the maturity of degradable plastics production processes will drive costs.

Gradually reduced to the acceptable range for downstream. With the maturity of various conditions, due to its unique properties, the development prospects of biodegradable polymer materials are extremely broad. At the same time, it also plays a huge role in reducing environmental pollution and creating a pollution-free environment for human beings. In the future, the development and research of biodegradable polymer materials should mainly focus on the competing polymer varieties in terms of the basic properties, molding and processing properties, and price of polymers.

About PeimePac

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

Network

With our team in China and Australia working as one, we reduce inefficiency so that you deal with one streamlined team from manufacturing right to delivery.

Service support team located in Guangzhou, the manufacturing hub of China, providing rapid response, and local industry knowledge. Warehouse and 3PL network located in Sydney, to provide rapid distribution, and delivery to your customers.

Top Packaging Companies in the World

Introduction

We are going to talk about the big packaging companies in the packaging industry today and the ways to succeed under the severe competition in the global packaging market.

Overview of Packaging Market

With the rapid growth of the consumer economy, the demand for packaging products has been increasing all over the world.

Higher requirements and standards compel the packaging companies to use different types of materials and implement new packaging technics.

As a result, competition has become more and more severe in the global packaging market. Many company's lacks of competence ended up with plunging business or bankruptcy.

The survivors strive to launch new products with different designs or materials to meet the various packaging requirements.

Meanwhile, some leading packaging companies might see it as an opportunity to stand out in the industry. Particularly for those with creative products and developed technology.

Packaging companies like those have always found a way to win the game despite the tough conditions.

Now let's see who are the winners all over the world.

Top 6 Packaging Companies in the World

1. INTERNATIONAL PAPER

International Paper is the largest leading packaging company in the world as a manufacturer of pulp and paper packaging.

The giant packaging company was established in 1898, with the headquarter in Memphis, Tennessee, the U.S. International paper has generated a revenue of $21.08 billion with 55,000 employees operating in more than 24 countries. The company manufactures a wide range of packaging products from envelopes to shipping containers.

Also, the company shows a great commitment to the business of recycling. As reported, International Paper has collected over 6 million tons of paper in the U.S. for recycling purposes.

2. WESTROCK

The WestRock is formed by the merger between MeadWestvaco and RockTenn. The company’s headquarter is in Norcross, Georgia, the U.S.

Established in 2015, the new packaging company has generated a revenue of $15 billion. Today, the company can support customers from diverse end markets around the world with 42,000 employees in 30 countries.

The products of WestRock include corrugated containers, Kraft paper, folding cartons, paperboard, displays, and protective packaging.

Like the other big packaging companies, West Rock cares about the environment by offering recycling packaging solutions.

Recently, WestRock acquired Kapstone in 2018. This enhances its ability to serve customers across systems. And make the specialty - craft paper products as an addition to their packaging solution portfolio.

Other than a packaging company, WestRock is also known as one of the largest integrated recyclers.

3. STORA ENSO

Stora Enso is a famous Finnish company specialized in solutions based on wood and biomass, which cover a range of industries and applications worldwide.

The success of the great packaging company is witnessed by various awards. The famous The Golden Egg Award in Sweden is one of them.

At the same time, the packaging company plays a leading role in the bio-economy as a key provider of renewable eco-friendly products in the global packaging markets.

The eco-friendly packaging products by Stora Enso offers a low-carbon alternative to products made from fossil-based or other non-renewable materials.

Currently, you can find their packaging solutions in a wide range of segments, from consumer markets like personal care, food, and beverages, to industrial applications including building, manufacturing, and textiles, etc.

4. SMURFIT KAPPA GROUP

Smurfit Kappa, headquartered in Dublin, is one of the leading providers of paper-based packaging solutions in the world.

As a constituent of the Financial Times Stock Exchange 100 Index AKA FTSE 100 Index, Smurfit Kappa has branches across 23 countries in Europe and 12 in the Americas.

The Ireland-based packaging company has generated revenue over $10 billion, with an employee base of 46,000 supporting about 350 production sites in 35 countries.

While constantly offering an excellent portfolio of solutions paper-packing, the packaging company cares about sustainability with sound contributions in multiple countries. The investment by Smurfit Kappa in Mexico recently on the topic of sustainable technology is known as one of the largest investments in the country in the Americas.

5. REYNOLDS GROUP HOLDINGS

Reynolds Group Holding is a leading global packaging company.

Based in Auckland, it manufactures and supplies foodservice and consumer beverage packaging products with aseptic packaging solutions including filling machines, cartons, and spouts.

The packaging company has a wide range of product lines, from consumer products such as wraps, aluminum foils, trays and pans, cups, and straws to packaging materials for household and automobile industries.

With an operation consisted of 5 segments, the packaging products of the company have serviced various industries including retailers mass merchandisers, grocery stores, warehouse clubs, drug stores, and military channels.

The company has an association with the former Reynolds Metal Company, which was the second-largest aluminum company in the United States.

6. AMCOR LIMITED